Nguyen Manchu General Manager of Taizhou Jianma Sewing Machine Co., Ltd.

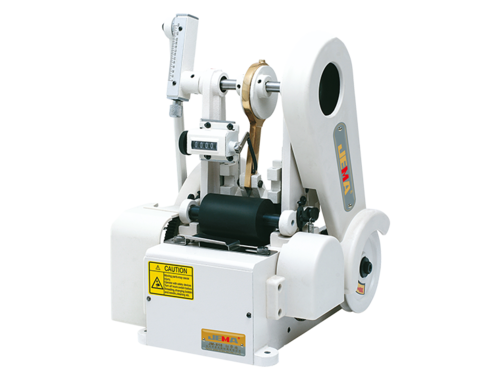

Taizhou Jianma Sewing Machine Co., Ltd. was established in In 1997, it is the only high-tech enterprise specializing in the production of sewing equipment such as tape cutting machines, computer tape cutting machines, and buttoning machines in China, integrating design, research and development, production, marketing and service. After more than ten years of dedicated development and continuous innovation, more than a dozen new products are put on the market every year to Satisfy user needs. The "JEMA" brand has become one of the leading brands of computerized tape cutting machines in China. It is sold at home and abroad with advanced technology, stable quality, reliable mechanical properties and favorable prices, and has won the dependence and praise of domestic and foreign users.

What prompted you to join the entrepreneurial army and choose the sewing machinery industry?

The first contact to work in the society is the sewing machine industry, and it is a technical development position. Long-term exposure coupled with environmental impact has given me an in-depth understanding of the industry. So when I saw the development prospects of the sewing machine industry, I decided to start a business and quickly invested in it.

The company has developed so far After 20 years of ups and downs, in the face of the overall economic downturn and the impact of e-commerce, how did Jianma respond? How do these issues affect Arrow Horse?

There must be some impact, especially the impact on the company's low-end market is relatively large, but the company's main client is mainly the high-end market, and the low-end market will not give up, so these objective problems will not have a fatal impact on us. Faced with these serious problems, we fully understand the market, produce products that meet customer needs, and constantly develop new products, follow the brand line, and continue to develop with quality as the word of mouth. "The most complete series".

Arrow Horse has developed For 20 years, and with a good reputation and reputation in the industry, what is the secret of Jianma's success?

since In 2008, after the company's brand and quality positioning were mid-to-high-end, we insisted on taking the road of unique innovation, independent research and development, not following the trend, and becoming stronger and more refined in the advantageous fields. Arrow Horse's reputation, reputation and commitment to customer service are the secret of our success.

What are the competitive advantages of Arrow Horse's products in the market?

Our goal is not to compare with domestic counterparts, but to compete with well-known international brands. Our product quality stability and reliability are no worse than theirs, and we even do better in terms of function, machine performance, ease of use, and improved efficiency. is our competitive advantage.

"JEMA Arrow Horse" brand is one of the leading brands of computerized tape cutting machine series in China. What kind of process has this brand gone through?

Arrow Horse has been in business so far In the past 20 years, it is one of the earliest companies in the sewing equipment industry. In 1997, the company was established in Taizhou, Zhejiang, and the product at the beginning of the business was a circular knife cutting machine. In 2003, the series of mechanical tape cutting machines represented by 817 were launched, and won 1 patent.

In 2005, although we also launched 120 computerized tape cutting machine products using electronic technology, Arrow Horse was still a follower in the market at that time. After comprehensive consideration, the company decided to open the market gap from the development of 120LR cold and hot knife models. Facts have proved that the original analysis and selection are completely correct. This model has a domestic market share of about 40% and a foreign market share of about 50%, which has established the market position of Jianma as one of the leading brands of tape cutting machines.

In 2007, we launched the simple computerized tape cutting machine 110 series, and won 3 patents. The introduction of the 110 series satisfies the vacancy between the mechanical and 120 computerized tape cutting machines, and becomes a powerful supplement to the highly targeted demand. In the same year, the 2373 button machine series products were developed and launched for the first time. While strengthening product research and development, it also made preliminary plans for the company's next positioning and direction.

go through After 5 years of market development and accumulation of tape cutting machine products, the core positioning of tape cutting machine as the company's main product has been continuously strengthened. We hope to become stronger and more refined in the two fields of tape cutting machine and buttoning machine, and build the "JEMA" brand into one of the leading brands of computerized tape cutting machine series in China.

In your opinion, what is the position of the Arrow Horse series in the market? What are the innovations?

exist In 2007, the sewing machine has entered the era of direct drive, but the direct drive technology of the buttoning machine is not yet on the market. In 2009, we launched the 2377D buttoning machine series, and took the lead in entering the era of direct-drive buttoning machines.

In 2013, the 2200 multi-functional ultrasonic computerized tape cutting machine series was launched, and won 3 patents. The powerful and unique automatic frequency-seeking technology of the 2200 series has been well received.

In 2015, the 150 multi-functional belt cutting machine series was launched and won 5 patents. The unique synchronous belt feeding technology, cornering, punching and receiving technology have been praised in the industry.

At the beginning of 2016, the second-generation automatic button feeding machine 988 was launched. The product has responded well since it was put on the market and has been recognized and affirmed by the market. After a year of research, we have developed the third-generation automatic button feeder 998 with "adjustment system for buckle adjustment and automatic width measurement and buckle system", which has won the EU CE certification and 14 technical patents.

On June 6, Arrow Horse will hold its 20th anniversary celebration, and some new products will be released at that time. What are the characteristics of Arrow Horse's new products this time? What is the competitive advantage in the market?

This new product launch will be launched The JM-998 automatic button feeding machine has the following features:

1. The original buckle adjustment platform:

When installing and debugging, or replacing different buttons, an adjustment platform is designed, and the longitudinal and transverse adjustment nuts can be easily adjusted arbitrarily to the desired position of the claw and the needle of the buttoning machine. Simple, convenient and practical. When the products on the market need to be adjusted, it is necessary to unscrew the fixing nuts around the bottom plate, manually move the position of the entire machine, and then lock the nuts, which is particularly laborious and time-consuming.

2. High-precision motor feeding system:

Using high-precision motor button feeding method, the button feeding position is extremely precise and accurate, which can be 100% accurate, soft button feeding, no noise, and long service life. The products on the market generally use the cylinder feeding method, and the cylinder is prone to wear and tear, the feeding is not in place, the service life is short, and it is unstable.

3. Crimp system:

Adopting stepper motor bidirectional crimping system: clockwise and counter-rotating crimping makes crimping more stable. Pneumatic pressure buckles are used on the market, and the pressure buckles are unstable.

4. Thickness measurement system:

When changing different buttons, just press the thickness measurement button, the thickness measurement plate will be automatically lifted, and the buttons can be easily put in, which is simple and convenient. The products on the market currently use manual mechanical ones, which are laborious.

5. Width measurement buckle:

When changing different buttons, just press the button of the width measuring button, the width measuring plate will automatically open, put down the button, the button feeding groove will be automatically adjusted, and the position of the blocking button will be automatically adjusted at the same time.

6. Electronic control system:

Developed by the company PLC integrated system, its running processor speed is fast, the failure rate is low, and the maintenance is very convenient. The machines on the market generally use the ARM system, which has the disadvantage that the processor speed is slow, and each part must be connected to a solid line, which is difficult and inconvenient to maintain.

7. Intelligent fault self-checking system:

up to 7 items of fault self-checking system, once a fault occurs, the fault and solution will be directly displayed on the screen, the maintenance is very fast, and the labor intensity of the mechanic is reduced. Products on the market do not yet have such a function.

8. Broken needle protection function:

In order to protect the personal safety of workers, the company's technicians have also developed a broken needle protection system for the buttoning machine. Once the needle is broken, the buttoning machine and the automatic button feeding machine will automatically stop working to prevent workers from hurting their fingers.

in addition, JM-998 automatic button feeding machine can be matched with various brands and models of buttoning machines such as Juji and Brother models, and can also be used with buttoning machines currently used by garment factories, which greatly saves the cost of repurchasing new buttoning machines.

Under the current trend of intelligent and automated manufacturing, how will Arrow Horse create greater glories in the future? As the helm of the Arrow Horse, do you have any plans?

In the future, we will adhere to the road of personalization, constantly learn advanced technology, be brave in innovation, strengthen product differentiation, and design and develop new products according to customer needs. Adhere to the road of serialization, intelligence and automation, adhere to the national, European and American quality standards, make after-sales service more meticulous and conscientious, and make due contributions to the Chinese sewing machine industry.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语