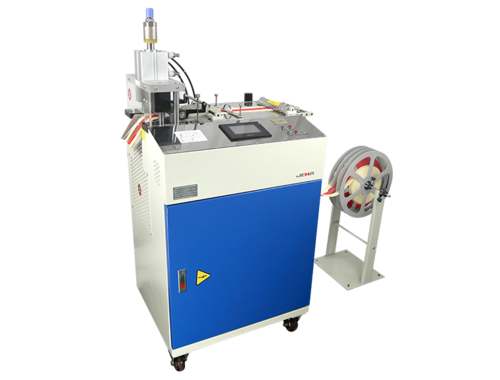

China Sale Automatic Fabric Tape Cutting Machine Maker

In today's highly competitive manufacturing landscape, ensuring product quality is paramount. One crucial aspect that significantly contributes to this quality is the efficient operation of the Auto Tape Cutting Machine. This sophisticated equipment plays a pivotal role in various industries, from automotive to electronics, by precisely cutting tapes to exact specifications. Understanding its importance in enhancing product quality requires delving into its functionalities and operational advantages.

The Auto Tape Cutting Machine automates the cutting process, eliminating human errors and inconsistencies that may arise from manual operations. By leveraging advanced technologies such as computer numerical control (CNC) and precision sensors, these machines can achieve remarkable accuracy in tape dimensions. This precision is critical in industries where even minor deviations can impact the functionality and performance of products.

Moreover, the Fabric Tape Cutting Machine Maker operates seamlessly across different types of tapes, including adhesive tapes used for packaging, electrical insulation, and masking. Its versatility extends beyond material type to encompass various widths and lengths, accommodating diverse manufacturing requirements. This flexibility not only enhances operational efficiency but also ensures uniformity in product specifications, thereby bolstering overall quality control measures.

In the realm of automotive manufacturing, where safety and reliability are paramount, the Auto Tape Cutting Machine plays a vital role. It ensures that adhesive tapes used in critical applications such as harnessing and sealing meet stringent standards. Precision cutting minimizes waste and optimizes material usage, contributing to cost efficiency while maintaining high-quality outputs.

Similarly, in electronics manufacturing, where miniaturization and precision are key, the China Auto Tape Cutting Machine facilitates the production of intricate components. It enables the precise application of tapes in circuit boards and electronic assemblies, safeguarding against electrical shorts and enhancing product durability. The machine's ability to handle delicate materials with minimal distortion ensures consistency in performance across electronic devices.

Beyond its technical capabilities, the Auto Tape Cutting Machine enhances workflow efficiency in production environments. By reducing setup times and cycle durations, it supports lean manufacturing principles and just-in-time inventory strategies. Manufacturers can respond swiftly to market demands without compromising on quality, thereby gaining a competitive edge in dynamic market conditions.

The integration of automation in tape-cutting processes also improves workplace safety by minimizing direct human involvement in potentially hazardous operations. Operators are tasked with overseeing machine operations and quality assurance rather than performing repetitive manual tasks. This shift not only enhances employee well-being but also allows skilled personnel to focus on value-added activities such as process optimization and troubleshooting.

Furthermore, advancements in machine learning and artificial intelligence are reshaping the capabilities of Auto Tape Cutting Machines. These technologies enable predictive maintenance, where machines can anticipate potential issues based on operational data and preemptively address them. Such proactive maintenance strategies enhance equipment reliability and prolong operational lifespan, reducing downtime and ensuring uninterrupted production schedules.

The Sale Automatic Tape Cutter represents more than just a tool for precise tape cutting. Its integration into manufacturing processes elevates product quality by ensuring consistency, precision, and operational efficiency across diverse industries. From automotive to electronics, its role in enhancing safety, reliability, and cost-effectiveness underscores its significance in modern manufacturing environments. As industries continue to evolve, embracing technological advancements in tape-cutting equipment will be crucial for maintaining competitive advantage and meeting evolving consumer expectations.

In conclusion, the Auto Tape Cutting Machine's impact on product quality is undeniable. Its precision, versatility, and automation capabilities make it indispensable across various manufacturing sectors. As industries strive for greater efficiency and reliability, investing in advanced tape-cutting technology will continue to be a cornerstone of successful manufacturing operations.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语

.png?imageView2/2/w/500/h/500/format/jp2/q/100)