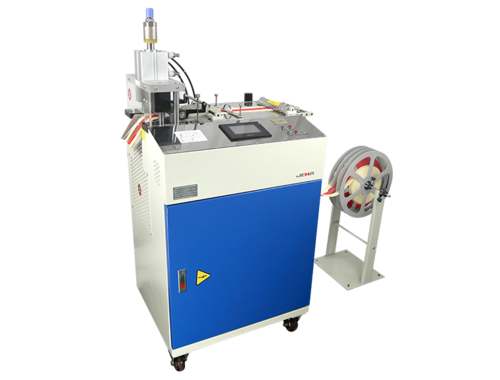

Multifunctional Computerized Tape Cutting Machine (Hot Knife) JM-150H

Fully automatic cutting, simple operation, wide application range, high cutting quality, smooth c...

In the ever-evolving world of textile manufacturing, efficiency and precision are paramount. Enter the automatic button sewing machine – a cutting-edge piece of equipment that is transforming the way buttons are attached to garments. With its advanced technology and streamlined operation, the automatic button sewing machine is not only revolutionizing garment manufacturing but also finding applications in various industries beyond fashion. Let's delve into how this innovative machine is reshaping production processes and unlocking new possibilities for manufacturers worldwide.

The automatic button sewing machine represents a significant advancement in garment manufacturing technology. Designed to automate the process of attaching buttons to clothing, this machine offers unparalleled speed, accuracy, and consistency compared to traditional manual methods. Equipped with sophisticated sensors, programmable settings, and high-speed stitching capabilities, the automatic button sewing machine can attach buttons of various sizes and styles with precision and efficiency, reducing production time and labor costs for manufacturers.

One of the key advantages of the automatic button sewing machine is its ability to streamline production processes and increase overall efficiency. By automating the button attachment process, manufacturers can significantly reduce the time and labor required to produce garments, allowing them to meet tight production deadlines and fulfill large orders with ease. Additionally, the machine's consistent stitching quality ensures uniformity across all garments, resulting in a higher quality finished product that meets customer expectations.

Moreover, the versatility of the automatic button sewing machine makes it suitable for a wide range of applications beyond garment manufacturing. From automotive upholstery and furniture upholstery to shoe manufacturing and accessories production, this versatile machine can be adapted to various industries and product types. With customizable settings and attachments, manufacturers can tailor the machine to suit their specific production needs, allowing for greater flexibility and scalability in manufacturing operations.

The adoption of automatic button sewing machines is also driving innovation and competitiveness in the textile industry. Manufacturers are continuously exploring new ways to enhance the capabilities and performance of these machines, incorporating features such as automatic thread trimming, button feeding systems, and programmable stitch patterns. These advancements not only improve efficiency and productivity but also enable manufacturers to create unique and complex button designs that were previously difficult or impossible to achieve with manual methods.

Furthermore, the integration of automatic button sewing machines into production lines is enabling manufacturers to embrace lean manufacturing principles and reduce waste. By minimizing manual handling and human error, these machines help to optimize production processes and eliminate unnecessary steps in the manufacturing workflow. This results in reduced material waste, improved resource utilization, and lower production costs, making it easier for manufacturers to remain competitive in today's fast-paced global market.

The environmental benefits of automatic button sewing machines are also worth noting. By optimizing production processes and reducing waste, these machines contribute to sustainability efforts within the textile industry. Additionally, the energy-efficient operation of automatic button sewing machines helps to minimize the environmental impact of manufacturing operations, further reducing the industry's carbon footprint and supporting eco-friendly practices.

In conclusion, the automatic button sewing machine is revolutionizing garment manufacturing and beyond, offering unparalleled efficiency, precision, and versatility in production processes. With its advanced technology and streamlined operation, this innovative machine is helping manufacturers worldwide to meet production demands, improve product quality, and drive innovation in the textile industry. As automation continues to reshape manufacturing processes, the automatic button sewing machine stands as a testament to the power of technology to transform traditional industries and unlock new possibilities for growth and success.

Fully automatic cutting, simple operation, wide application range, high cutting quality, smooth c...

Fully automatic cutting, easy operation. Wide application range, high cutting quality, smooth cut...

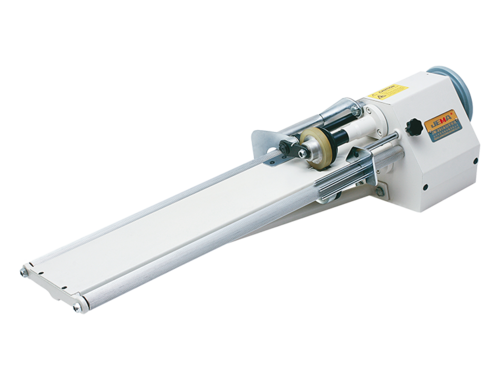

special function: This sturdy machine is completely used for the manufacture of braided belts....

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...