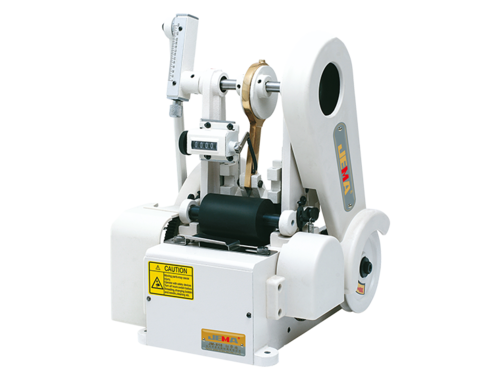

China Custom Automatic Wire Cutter Fabric Cloth Velcro Cutting Machine Supplier

Automatic Velcro Cutting Machines are essential tools for manufacturers looking to streamline production processes and enhance efficiency. These machines are designed to provide accurate, consistent cuts for Velcro, improving the overall quality of the final product. However, like any piece of machinery, China Automatic Velcro Cutting Machines can experience issues that may affect their performance. Understanding these common problems and knowing how to address them can help ensure smooth operations and reduce downtime.

One of the common issues with Automatic Velcro Cutting Machines is inconsistent cutting accuracy. While these machines are designed to deliver precise cuts, factors such as worn-out blades or incorrect settings can result in uneven or inaccurate cuts. To resolve this, it is important to regularly inspect the cutting blades for wear and tear. If the blades are dull or damaged, they should be replaced. Additionally, operators should ensure that the machine is correctly calibrated for the material and cutting size. Regular maintenance and calibration checks can go a long way in maintaining cutting accuracy.

Another frequent issue with Automatic Velcro Cutting Machines is jamming or clogging. Velcro, being a fabric-based material, can sometimes get caught in the machine’s cutting mechanism, especially if there are threads or fibers that obstruct the blades. This can result in delays in production and potential damage to the machine. To solve this problem, it is recommended to clean the machine regularly and ensure that no material buildup occurs in the cutting area. Regular maintenance, such as cleaning and oiling moving parts, can also help prevent jamming and keep the machine running smoothly.

The Automatic Velcro Cutting Machine may also face issues with uneven tension during the cutting process. If the Velcro material is not fed properly into the machine, it may result in inconsistent tension, which can result in irregular cuts. This can be particularly problematic when producing large batches of Velcro pieces that need to be uniform in size and shape. To address this issue, operators should ensure that the Velcro is properly aligned and tensioned before feeding it into the machine. Additionally, using a machine with adjustable tension controls can help manage material movement and ensure consistent cuts throughout the production process.

In some cases, the Automatic Velcro Cutting Machine may experience inconsistent cutting speed. This can occur if the machine is not properly maintained or if the cutting mechanism is worn out. A decrease in cutting speed can result in delays in production and an overall decrease in efficiency. To fix this issue, it is important to monitor the machine’s performance regularly and perform maintenance as needed. Cleaning the machine’s motor and lubricating moving parts can help maintain ideal cutting speeds. If speed issues persist, it may be necessary to consult a technician to assess the machine’s internal components.

Another issue with Custom Automatic Wire Cutters is incorrect settings or improper calibration, which can result in deviations in cut size or material waste. Incorrect settings may cause the machine to cut too much or too little, impacting the overall quality and quantity of the final product. To avoid this issue, operators should carefully review the machine’s settings before starting the cutting process. Additionally, it is essential to calibrate the machine regularly to ensure that it is cutting according to the required specifications. Operators should follow the manufacturer’s guidelines for calibration to maintain ideal performance.

Lastly, wear and tear of the machine’s mechanical components can cause performance issues over time. Parts such as gears, belts, and bearings can degrade with prolonged use, resulting in reduced efficiency or mechanical failure. Regular inspection and replacement of worn parts are essential to keeping the Automatic Velcro Cutting Machine in good working condition. Having a preventive maintenance schedule in place can help identify potential issues before they cause major disruptions.

In conclusion, while Automatic Velcro Cutting Machines are essential for improving efficiency and cutting precision in Velcro production, they are not without their challenges. Common issues such as inconsistent cutting, jamming, uneven tension, electrical malfunctions, and incorrect settings can affect the machine’s performance. However, by performing regular maintenance, ensuring proper calibration, and addressing minor issues promptly, manufacturers can keep their Fabric Cloth Cutting Machine Suppliers running smoothly and reduce downtime. Proper care and attention to detail can help ensure that these machines continue to enhance production efficiency and maintain high product quality.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语

.png?imageView2/2/w/500/h/500/format/jp2/q/100)