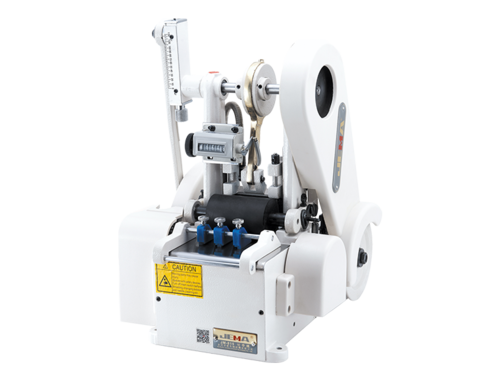

In the landscape of industrial machinery, the Computer Tape Cutting Machine equipped with Hot Knife Infrared technology emerges as a groundbreaking tool, revolutionizing material cutting in various industries. This specialized machine, integrating cutting-edge infrared technology with hot knife mechanisms, offers unparalleled precision, efficiency, and versatility in cutting tapes, fabrics, films, and other materials.

At its core, the Computer Tape Cutting Machine with Hot Knife Infrared technology represents a quantum leap in cutting precision. Its fusion of computer-controlled accuracy and the advanced heat-emitting capabilities of infrared technology ensures immaculate, precise, and efficient cutting of diverse materials, meeting stringent specifications demanded in a wide array of industrial processes.

The standout feature of this machine lies in its unparalleled precision. Harnessing the power of infrared technology coupled with hot knife mechanisms, it delivers immaculate and consistent cuts with minimal material waste. This precision is particularly crucial in industries reliant on accuracy and consistency, such as textiles, automotive manufacturing, and packaging.

Versatility is another hallmark of the Computer Tape Cutting Machine with Hot Knife Infrared technology. Its adaptability to cut various materials of different widths, thicknesses, and textures makes it an invaluable asset in industries requiring tailored or standardized cuts. From adhesive tapes to specialized fabrics used in high-tech applications, this machine caters to diverse cutting needs, optimizing production efficiency.

The incorporation of Hot Knife Infrared technology augments the machine's performance. Unlike conventional cutting methods, the combination of infrared heat and hot knife precision ensures clean and sealed edges without fraying or distortion, particularly advantageous for synthetic materials or tapes that require precise cuts without compromising their integrity.

The efficiency and speed of the Computer Tape Cutting Machine are remarkable. Its automated processes, combined with rapid and precise cutting capabilities, contribute to increased productivity, minimized material waste, and streamlined manufacturing operations.

In conclusion, the Computer Tape Cutting Machine (Hot Knife Infrared) symbolizes the pinnacle of precision cutting technology. Its integration of computer-controlled precision, Hot Knife Infrared technology, versatility, and efficiency positions it as an indispensable asset in industries reliant on precise and efficient material cutting processes.

As industries continually seek heightened accuracy, efficiency, and versatility in material cutting operations, the role of specialized machines like the Computer Tape Cutting Machine (Hot Knife Infrared) continues to evolve, fostering advancements in production processes and contributing to enhanced productivity and quality across various sectors.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语