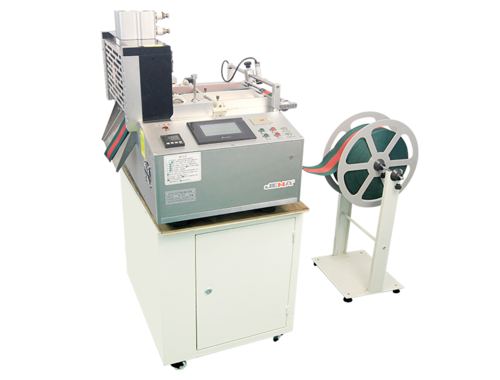

In the ever-evolving landscape of manufacturing, where precision and versatility are paramount, the Tape Cutting Machine with Cold and Hot Knife Technologies has emerged as a cutting-edge solution, seamlessly integrating both cold and hot cutting capabilities. This innovative machine is reshaping the tape cutting processes across industries by offering a multifunctional approach that caters to a wide range of materials and applications. Let's delve into how this advanced machine is revolutionizing manufacturing, providing a versatile and precise cutting solution.

The defining feature of the Tape Cutting Machine with Cold and Hot Knife Technologies lies in its unique ability to switch between cold and hot cutting methods. Unlike traditional cutting machines that are limited to one technique, this advanced equipment provides manufacturers with the flexibility to choose the most suitable cutting method for different materials and applications. The integration of both cold and hot knife technologies positions it as a comprehensive tool for diverse cutting needs.

One of the standout features of this cutting-edge machine is its adaptability to various materials. The cold knife technology excels in cutting materials like fabrics, tapes, and foams, ensuring clean and precise cuts without generating heat. On the other hand, the hot knife technology is particularly effective for materials that require sealing edges or preventing fraying, such as synthetic fabrics and plastic films. The ability to seamlessly switch between these cutting methods makes the machine versatile enough to handle a wide array of materials in industries like textiles, packaging, and automotive.

In the textile industry, where the precision of cuts directly impacts the quality of the final product, the Tape Cutting Machine with Cold and Hot Knife Technologies stands out. The cold knife technology ensures clean cuts in fabrics, maintaining the integrity of the material, while the hot knife technology enables sealing edges to prevent fraying. This versatility is crucial for manufacturers producing garments, upholstery, and other textile-based products.

In the packaging industry, where the sealing and finishing of edges are essential for product integrity, this machine proves invaluable. The hot knife technology creates sealed edges in materials like plastic films, ensuring a secure and professional finish. Additionally, the cold knife technology offers precision in cutting tapes and labels, contributing to the overall quality and appearance of packaged products. The multifunctional capabilities of the machine address the diverse cutting needs within the packaging sector.

The efficiency of the Tape Cutting Machine with Cold and Hot Knife Technologies is evident in its ability to enhance productivity. The automated nature of the machine, coupled with the versatility of cutting options, significantly reduces processing times. Manufacturers can seamlessly switch between cold and hot knife methods, adapting to different materials without the need for manual adjustments or changing equipment. This efficiency is particularly advantageous in industries with high-volume production requirements.

Manufacturers of this advanced cutting machine continually invest in research and development to enhance its features. Advanced models now come with improved heating elements for hot knife technology, faster switching mechanisms between cold and hot modes, and user-friendly interfaces. These enhancements cater to the evolving needs of industries that demand not only precision cutting but also efficiency and adaptability in their manufacturing processes.

The success stories from manufacturing plants that have adopted the Tape Cutting Machine with Cold and Hot Knife Technologies underscore its impact on efficiency and versatility. Mark Reynolds, a production supervisor in a packaging facility, notes, "This machine has streamlined our production process. The ability to switch between cold and hot knife technologies has allowed us to handle diverse materials without the need for multiple machines. It's a game-changer for us."

As industries continue to seek cutting solutions that offer versatility and precision, the Tape Cutting Machine with Cold and Hot Knife Technologies stands as a pivotal advancement in the field. Its unique combination of both cutting methods addresses the intricate and diverse cutting needs of modern manufacturing. As technology continues to advance, these cutting machines are likely to see further refinements, contributing to the continued evolution of manufacturing processes worldwide.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语