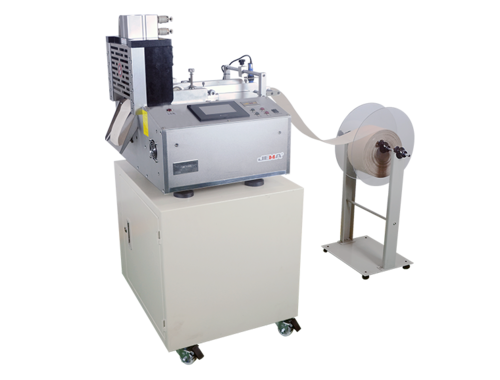

In the realm of industrial machinery, the evolution of cutting technologies is rapidly transforming manufacturing processes. A prime example of this transformative shift is embodied in the Computer Tape Cutting Machine, a versatile powerhouse that has now taken the precision game to the next level with both Cold and Hot cutting modes. This dual-mode capability is revolutionizing the way tapes, films, and adhesive materials are processed, providing industries with unprecedented flexibility and efficiency.

The Dual Dynamics of Cold and Hot Cutting:

At the core of the Computer Tape Cutting Machine's innovation is its ability to seamlessly transition between Cold and Hot cutting modes. This dual functionality allows manufacturers to tailor their cutting processes to the specific requirements of different materials.

In Cold mode, the machine employs a non-contact cutting method, utilizing blades or ultrasonic technology to precisely cut through materials without generating heat. This mode is particularly beneficial for sensitive materials that may be adversely affected by thermal stress, ensuring clean and accurate cuts without compromising material integrity.

Conversely, Hot cutting mode introduces heat into the equation. This mode is ideal for materials that benefit from a sealed edge or where precision is critical. The application of heat ensures that the edges are sealed, preventing fraying or unraveling. It's particularly effective for materials like synthetic fabrics, tapes, and films.

Versatility Redefined:

The integration of both Cold and Hot cutting modes in a single machine marks a paradigm shift in versatility. Manufacturers no longer need separate machines for different cutting methods, streamlining production processes and significantly enhancing operational efficiency.

The versatility of the Computer Tape Cutting Machine is further exemplified by its capacity to handle an extensive range of materials. From delicate textiles and adhesive tapes to robust films and laminates, this machine can adapt to the unique characteristics of each material, ensuring a consistent and high-quality end product.

Precision at Its Pinnacle:

Precision is paramount in manufacturing, and the Computer Tape Cutting Machine delivers on this front with unparalleled accuracy. In Cold mode, the non-contact cutting mechanism allows for intricate designs and shapes without the risk of material distortion or damage. This is particularly advantageous in industries where precision is critical, such as in the production of medical tapes or electronic components.

The Hot cutting mode, on the other hand, ensures that materials with thermally sensitive properties are cleanly and precisely cut. The application of heat not only seals the edges but also prevents fraying, ensuring a finished product that meets the highest standards of quality.

Efficiency and Speed:

In the fast-paced world of manufacturing, efficiency and speed are paramount. The Computer Tape Cutting Machine excels in both domains. The ability to switch seamlessly between Cold and Hot cutting modes allows for continuous and uninterrupted production, eliminating the need for frequent machine changes or downtime.

The intuitive controls and programmable settings of the machine contribute to further efficiency gains. Manufacturers can easily set parameters for different materials and cutting patterns, ensuring a swift and accurate response to varying production requirements. This level of automation not only boosts efficiency but also minimizes the margin for error.

Applications Across Industries:

The adaptability and precision of the Computer Tape Cutting Machine make it a versatile asset across a myriad of industries. In textile manufacturing, for example, it can precisely cut intricate patterns for garments or textiles used in medical applications. In the packaging industry, the machine's ability to handle various materials with both Cold and Hot cutting modes makes it invaluable for custom packaging solutions.

Moreover, in the automotive sector, the Computer Tape Cutting Machine finds applications in the precise cutting of adhesive materials used in assembly processes. The dual-mode capability ensures that the machine can handle both heat-sensitive and heat-sealable materials, catering to the diverse needs of the automotive manufacturing landscape.

While the Computer Tape Cutting Machine represents a leap forward in cutting technology, there are challenges to consider. The integration of dual cutting modes requires sophisticated controls and mechanisms, demanding a higher level of technical expertise for operation and maintenance.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语