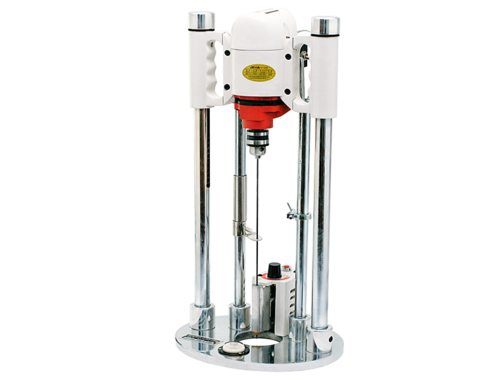

In the world of industrial sewing, choosing the right equipment is crucial for ensuring both productivity and quality. One of the essential machines in garment production, particularly in the apparel industry, is the Industrial Button Sewing Machine. This machine plays a vital role in attaching buttons to various types of clothing and accessories. However, not all button sewing machines are created equal. To get the performance, it is important to understand which features to look for when selecting a Custom Industrial Button Sewing Machine.

One of the factors to consider when choosing an Industrial Button Sewing Machine is the variety of stitches it can produce. Different garments and button types require different stitching patterns to ensure that the button is securely attached. While basic button sewing might only require a simple stitch, more complex designs or buttons might demand additional stitch patterns, such as reinforcement stitches or decorative designs.

An Industrial Button Sewing Machine with multiple stitch options gives manufacturers more flexibility. The machine should be able to provide a stable and secure stitch for a wide variety of button sizes and types. This versatility is important, especially when working with different fabrics, as the stitch quality can vary depending on the material.

The ability to adjust the buttonhole size is another critical feature when selecting an Industrial Button Sewing Machine. Different garments require buttons of various sizes, and the machine must accommodate these variations without compromising stitch quality or speed. A machine with an adjustable buttonhole feature allows for flexibility in both the size of the button and the garment, ensuring that buttons fit properly and securely.

This adjustability also helps to reduce material waste, as the machine can be tailored to the specific dimensions of each project. Whether you’re working with large coats or small shirts, the right adjustments can make all the difference in the finished product.

Speed is an essential factor in any industrial sewing machine, and the Industrial Button Sewing Machine is no exception. High-speed stitching capabilities are important in a production environment where efficiency is key. A faster machine ensures that workers can complete more tasks in less time, increasing productivity and reducing labor costs.

However, it is important to find a balance between speed and stitch quality. The ideal Cheap Button Attach Machine should maintain a high stitching speed while still producing high-quality seams that are strong and durable. Machines with adjustable speed controls allow operators to find the right pace for different tasks, helping to avoid mistakes that might occur with overly fast speeds.

Industrial machines are designed for heavy-duty use, so it is essential that the Industrial Button Sewing Machine is built to last. Durability is a crucial factor, as these machines are often used for long shifts in high-volume environments. Machines made with high-quality, sturdy materials can withstand the wear and tear that comes with constant use.

An automatic button feeder is a convenient feature in an Industrial Button Sewing Machine that can significantly improve efficiency. This feature automates the process of feeding buttons into the machine, reducing the need for manual intervention and reducing the chance of human error. By automating this step, the machine can work continuously without pauses for button placement.

Thread tension is another critical factor that can affect the quality of the stitches produced by a Button Hole Industrial Machine Price. Inconsistent thread tension can result in weak or uneven stitching, which can cause buttons to come loose over time. Machines with adjustable thread tension controls give operators the ability to fine-tune the tension according to the fabric and button type being used.

Choosing the right Industrial Button Sewing Machine is an important decision for any garment manufacturer. To ensure that you select the machine for your needs, it is important to look for features such as stitch variety, button hole size adjustability, speed, durability, and ease of maintenance. With the right machine, manufacturers can improve efficiency, reduce errors, and produce high-quality garments. By considering all these factors, you can make an informed decision and invest in a machine that will meet the demands of your production process.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语