The metal laser cutting machine is made by focusing the laser beam into a very small spot with its smallest diameter (can be less than 0.1mm), so that the focus can reach a high power density (can exceed 106W/cm2). At this time, the heat input by the beam (converted by light energy) far exceeds the part reflected, conducted or dispersed by the material, and the material is quickly heated to the vaporization temperature, which evaporates to form a hole. With the relative linear movement of the beam and the material, the holes are connected to form a slit with a narrow width (such as about 0.1mm). The thermal effect of trimming is very small, and there is basically no workpiece deformation. The auxiliary gas suitable for the material to be cut is also added during the cutting process. When cutting steel, oxygen is used as an auxiliary gas to cause an exothermic chemical reaction with the molten metal to oxidize the material, and at the same time, it helps to blow away the slag in the cutting seam. Compressed air is used to cut plastics such as polypropylene, and inert gas is used to cut flammable materials such as cotton and paper. The auxiliary gas entering the nozzle also cools the focusing lens, preventing fumes from entering the lens holder and contaminating the lens and causing it to overheat. It has the following processing features:

①The flexibility of laser and cutting machine processing is strong

The metal laser cutting machine does not require the preparation of molds and auxiliary consumables. Whether it is a single product, a variety of low-volume products or different graphics and text processing requirements, it can be processed immediately.

②Advanced processing technology

After the laser is focused, the spot diameter of the metal laser cutting machine is small, the processing is fine, the heat-affected zone to the processing material is small, and the workpiece is basically not deformed. The laser beam can process the workpiece inside the partition or sealed container through the transparent object, and can focus on the wavelength-level high-energy light spot for micro-region processing, and can complete some processes that cannot be completed by conventional methods.

③Low processing cost and simple operation

Laser processing does not require additional work and consumables. As long as the laser works normally, continuous processing can be performed for a long time. The processing speed is fast, the cost is low, the automatic production can be completed by computer control, and the operation is simple and convenient to change.

④Conform to environmental protection requirements

The laser processing of metal laser cutting machine is non-toxic, harmless, clean and hygienic, which meets the environmental protection requirements of production in various countries and avoids the constraints formed by corrosion, silk screen and other processes.

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Web Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Product Search

Exit Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

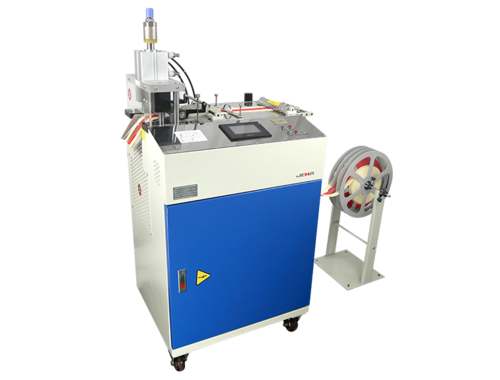

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features ...

View this series of products

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features high speed: ...

View this series of products

Computer tape cutting machine (cold, hot infrared) JM-120HLR

Fully automatic cutting, simple operation, wide application range and high cutting quality. Features high speed: It can cut 70~90 pieces p...

View this series of products

Industry News

Is the higher the laser beam power the better the cutting effect?

PREV:How to choose a high-quality laser cutting machine?NEXT:What materials can the fiber laser cutting machine process?

Recommended Products

-

Ultrasonic Computerized Tape Cutting Machine (Right Angle) JM-2100

Fully automatic cutting, easy operation. Wide application range, high cutting quality, smooth cut...

-

Ultrasonic Computerized Tape Cutting Machine (Right Angle / Corner) JM-2200

Fully automatic cutting, simple operation, wide application range, high cutting quality, smooth c...

-

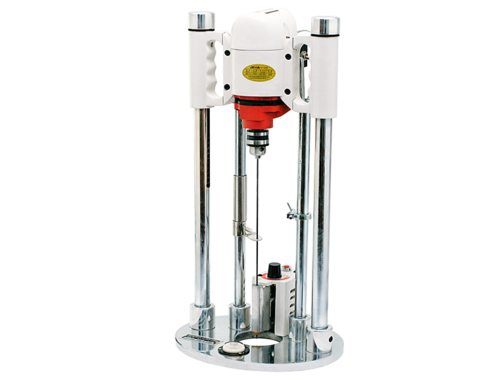

Electric cutting machine JM-3

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...

-

High-speed cloth drilling machine (heating) JM-1-2

Features This machine is one of the indispensable special equipments in garment production. It...

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

©2021 Taizhou JEMA Sewing Machine Co., Ltd. Custom Elastic Tape Cutting Machine Manufacturers

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语