Mechnical Cutting Machine is a tool used in manufacturing processes for cutting and bending metal. This cutting process produces parts in different shapes and sizes. It is commonly used in various industries. It has several advantages. It is cheaper compared to other cutting processes. Moreover, it can create parts in 3 dimensions. This cutting process can also produce parts in perfect angles.

Several types of mechanical cutting machines are available in the market. The main applications of these machines are in defense, aerospace, and automotive. This market is expected to witness robust growth during the forecast period. Moreover, it is expected to be driven by technological innovations. In addition, it is expected to be augmented by the presence of major defense and aerospace players.

Metal cutting machines are widely used in various application industries. The major applications of these machines are in defense, aerospace, automotive, and composites industries. The market is expected to grow owing to the growth in demand for advanced metal cutting machines. It is also expected to benefit from the increased spending on military and aerospace products. It is also expected to benefit from the increasing demand for commercial aircrafts. The market is expected to grow with a 4.3% CAGR over the forecast period.

Another important application of these machines is in cutting rotary blades. They can also be used to cut exterior components of an automobile. It is also used to cut door panels. Besides, they provide the necessary size and shape for the desired product. They also offer a surface texture.

Laser Cutting is another cutting process. This process is used in the manufacturing of parts that require finishing, delivery, and assembly. It eliminates the need for contact with the material. In addition, it reduces the possibility of damage and contamination. It also prevents wear and deformation. It is also considered to be a technical challenge. It is used by thousands of manufacturing industries.

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

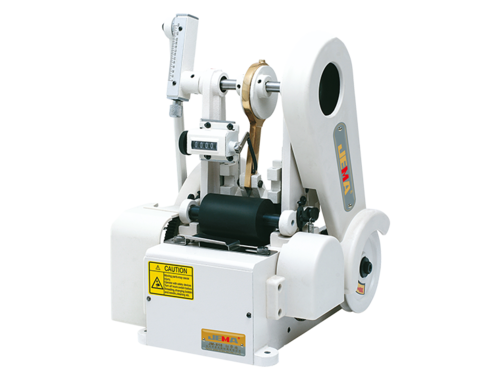

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Web Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Product Search

Exit Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features ...

View this series of products

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features high speed: ...

View this series of products

Computer tape cutting machine (cold, hot infrared) JM-120HLR

Fully automatic cutting, simple operation, wide application range and high cutting quality. Features high speed: It can cut 70~90 pieces p...

View this series of products

Industry News

Home / News / Industry News / Mechnical Cutting Machine is a tool used in manufacturing processes for cutting and bending metal

Mechnical Cutting Machine is a tool used in manufacturing processes for cutting and bending metal

PREV:The Velcro Cutting Machines are durableNEXT:What are the advantages of a multi-function cutting machine?

Recommended Products

-

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold ...

-

Computer tape cutting machine (rounded corners) JM-120R

Fully automatic cutting, simple operation, wide application range and high cutting quality. It ca...

-

Tape cutting machine (rounded corners) JM-818

Features Shapes such as rounded corners, ellipses, full circles, etc. can be cut off. It ...

-

Round knife cutting machine JM-100

Features The JM-60/70 miniature cutting machine is suitable for cutting curves, small arcs and...

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

©2021 Taizhou JEMA Sewing Machine Co., Ltd. Custom Elastic Tape Cutting Machine Manufacturers

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语