In the realm of modern manufacturing and packaging, the Computer Tape Cutting Machine, featuring a hot knife, stands as a technological marvel that revolutionizes the way tape materials are cut and processed. This cutting-edge machine combines precision, speed, and versatility to meet the demands of various industries, from packaging to electronics. With its remarkable capabilities, the Computer Tape Cutting Machine (Hot Knife) streamlines production processes, reduces waste, and ensures the highest standards of accuracy. In this comprehensive guide, we'll explore the world of the Computer Tape Cutting Machine (Hot Knife), emphasizing its exceptional attributes and its pivotal role in enhancing efficiency across a spectrum of industries.

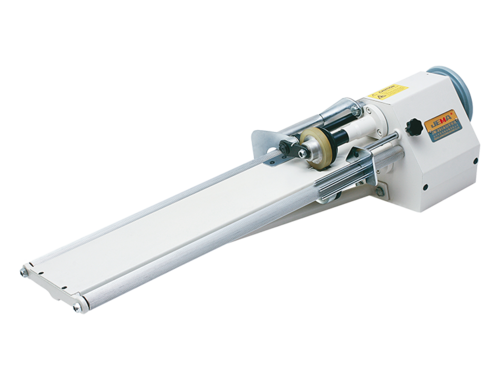

The Computer Tape Cutting Machine (Hot Knife) is a sophisticated piece of equipment designed to automate the cutting and processing of adhesive tapes, fabric tapes, hook and loop fasteners, and various other materials. Its primary feature is a hot knife, which uses controlled heat to make precise cuts, sealing the edges of the materials to prevent fraying. This innovative machine is computer-controlled, enabling customization and ensuring consistent, high-quality cuts with minimal operator intervention.

Precision Cutting: The hot knife technology ensures clean and precise cuts, reducing waste and ensuring product integrity.

Versatility: It can handle a wide range of materials, from adhesive tapes to webbing, labels, and more.

Speed and Efficiency: The computer-controlled automation significantly speeds up the cutting process, improving overall production efficiency.

Customization: The machine allows for easy adjustments in cutting lengths, angles, and shapes, catering to various product specifications.

Quality Control: Consistent and accurate cuts enhance the quality of the end product, meeting the highest industry standards.

Reduced Labor Costs: Automation reduces the need for manual labor in cutting and processing tasks, saving on labor costs.

Safety: The hot knife technology minimizes frayed edges, reducing the risk of injury during handling.

This advanced cutting machine finds applications across a spectrum of industries:

Packaging: It plays a vital role in the packaging industry for precise cutting of adhesive tapes used in sealing and bundling products.

Textiles and Apparel: The machine is used to cut fabric tapes, webbing, and hook and loop fasteners in textile and garment manufacturing.

Electronics: In the electronics industry, it is employed for cutting and processing materials used in circuit board assembly.

Automotive: The machine is used for cutting automotive materials such as adhesive tapes and foam gaskets.

Medical: It assists in the precise cutting of medical tapes and materials used in the production of medical devices.

Selecting the appropriate Computer Tape Cutting Machine (Hot Knife) involves considering factors such as the types of materials to be cut, cutting speed requirements, and the level of automation needed. Evaluating the machine's computer control capabilities and customization options is crucial to ensure it meets the specific needs of the application.

The Computer Tape Cutting Machine (Hot Knife) is a symbol of precision and efficiency in the world of cutting and processing materials. Its hot knife technology, coupled with computer control, ensures the highest level of accuracy and automation. Whether it's enhancing packaging processes, streamlining textile manufacturing, or meeting the demands of the electronics industry, this machine stands as a testament to its exceptional capabilities and performance.

In your pursuit of precision and efficiency in material cutting and processing, the Computer Tape Cutting Machine (Hot Knife) is the ultimate choice. Embrace its attributes and experience the transformative impact it can have on your production processes. Invest in the Computer Tape Cutting Machine (Hot Knife) today and elevate your manufacturing and processing capabilities to new heights of accuracy and efficiency.

English

English 中文简体

中文简体 Español

Español Tiếng Việt

Tiếng Việt Português

Português Türk

Türk

.png?imageView2/2/w/500/h/500/format/jp2/q/100)