In the fast-paced world of manufacturing, where precision and efficiency are paramount, the

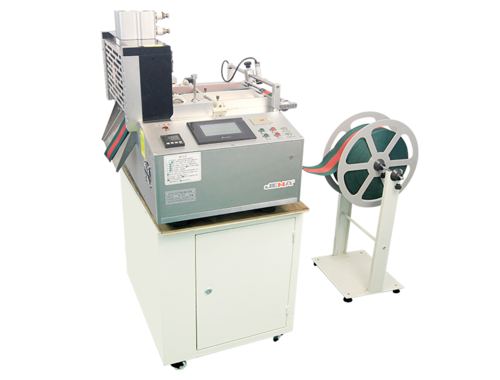

Computerized Tape Cutting Machine with Cold Knife has emerged as a game-changing innovation, setting new standards in the cutting-edge technology landscape. This advanced machine, equipped with a cold knife, combines computerized precision with the ability to handle various materials, revolutionizing the tape cutting process across industries. Let's delve into how this state-of-the-art machine is transforming manufacturing, delivering unparalleled accuracy and efficiency.

The defining feature of the Computerized Tape Cutting Machine with Cold Knife lies in its cutting-edge technology, which integrates computerized controls with a cold knife mechanism. Unlike traditional cutting methods that may generate heat during the process, the cold knife ensures that the material being cut remains unaffected by temperature changes. This is particularly crucial when dealing with sensitive materials such as adhesives, tapes, and other substrates prone to heat damage.

One of the standout features of this advanced machine is its computerized precision, allowing for intricate and customizable cutting patterns. The integration of computer controls provides manufacturers with the flexibility to create complex shapes and sizes, catering to diverse industry requirements. Whether cutting tapes for packaging, automotive applications, or medical devices, the Computerized Tape Cutting Machine with Cold Knife delivers consistent and precise results.

In industries where speed is of the essence, the efficiency of the Computerized Tape Cutting Machine shines. The automated nature of the machine significantly reduces processing times, contributing to higher production rates. This is especially advantageous in high-volume manufacturing settings, where meeting tight deadlines and maintaining consistent quality are critical factors.

The versatility of the Computerized Tape Cutting Machine with Cold Knife extends to its ability to handle a wide range of materials. From adhesive tapes and Velcro to foams and films, this machine's cold knife technology ensures clean and precise cuts without compromising the integrity of the materials. This versatility positions the machine as an indispensable tool in industries with diverse material cutting needs.

In the packaging industry, where precise cutting of adhesive tapes is crucial for product integrity, the Computerized Tape Cutting Machine with Cold Knife proves invaluable. The cold knife technology prevents the adhesive from melting or deforming during the cutting process, ensuring that tapes maintain their adhesive properties. This is essential for achieving strong and reliable seals in packaging applications.

The adaptability of the Computerized Tape Cutting Machine with Cold Knife extends to industries requiring intricate patterns and designs. In the textile and automotive sectors, where precision cutting of materials is essential for crafting intricate components, this machine excels. The computerized controls allow for the creation of complex shapes and designs with ease, meeting the demands of modern manufacturing processes.

Manufacturers of the Computerized Tape Cutting Machine with Cold Knife continually invest in research and development to enhance its features. Advanced models now come with improved cutting speeds, enhanced software capabilities, and user-friendly interfaces. These advancements cater to the evolving needs of industries that demand not only precision cutting but also efficiency and adaptability in their manufacturing processes.

The success stories from manufacturing plants that have adopted the Computerized Tape Cutting Machine with Cold Knife underscore its impact on efficiency and quality. Lisa Roberts, a production manager in a packaging facility, notes, "Since integrating this advanced cutting machine into our production line, we've seen a remarkable increase in efficiency. The precision and speed with which it cuts adhesive tapes have significantly improved our packaging processes."

As industries continue to prioritize precision, efficiency, and adaptability in manufacturing, the Computerized Tape Cutting Machine with Cold Knife stands as a pivotal advancement in the field. Its unique combination of computerized controls and cold knife technology addresses the evolving needs of modern manufacturing, providing a solution that ensures accuracy, versatility, and speed. As technology continues to advance, these cutting machines are likely to see further refinements, contributing to the continued evolution of manufacturing processes worldwide.