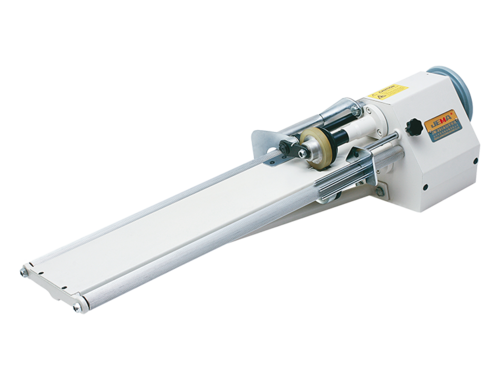

Sale OEM Industrial Rectangle Button Manufacturing Machine Maker

In the world of manufacturing, efficiency and cost-effectiveness are key to success, especially when it comes to large-scale production. One area where these factors are crucial is in the production of buttons, a small yet essential component in the garment industry. The Industrial Button Machine has emerged as a solution that addresses the demands of high-volume button manufacturing. This article will delve into the benefits of using a Sale Industrial Button Machine for large-scale production, highlighting its role in streamlining processes and enhancing productivity.

The Industrial Button Machine is designed to handle the rigors of mass production with ease. Its high-speed operation and automated features allow for a significant increase in output compared to manual methods. This efficiency is crucial for businesses that require a large number of buttons for their products, as it reduces the time taken to produce each batch. By automating the button-making process, companies can meet tight deadlines and increase their production capacity without a proportional increase in labor costs.

One of the primary benefits of using an Industrial Button Machine is the precision and consistency it offers. Manual button-making can be prone to human error, resulting in variations in size, shape, and quality. However, it ensures that each button produced is identical to the next, maintaining a uniform standard across all products. This consistency is particularly important in industries where brand reputation is tied to product quality, as it helps to maintain a professional image and customer trust.

The cost-effectiveness of an Industrial Button Machine cannot be overstated. While the initial investment may be significant, the long-term savings in labor and material costs can be substantial. By reducing the need for manual labor, businesses can save on wages and training expenses. Additionally, the machine's efficiency in material use means less waste is generated, further reducing costs. Over time, the savings from these reduced expenses can far outweigh the initial investment in the machine.

As market demands fluctuate, the ability to scale production up or down is essential. An Industrial Button Machine offers this flexibility, allowing businesses to adjust their output to meet changing needs without significant disruption. This scalability is particularly beneficial for companies that operate in competitive markets or have seasonal production cycles, as it enables them to respond quickly to changes in demand.

Quality control is a critical aspect of any manufacturing process, and the OEM Button Manufacturing Machine plays a significant role in this regard. By automating the button-making process, the machine reduces the potential for human error, resulting in a higher-quality product. Additionally, many Industrial Button Machines come equipped with built-in quality control features that can detect and correct issues during production, further ensuring that only the buttons are produced.

In today's environmentally conscious world, the impact of manufacturing processes on the environment is a significant concern. An Industrial Button Machine can help to reduce the environmental footprint of button production. By reducing waste and enhancing material use, these machines contribute to a more sustainable production process. This not only benefits the environment but can also enhance a company's green credentials, which can be a valuable asset in the eyes of eco-conscious consumers.

The use of an Industrial Button Machine also has implications for workplace safety. Manual button-making can involve the use of heavy machinery and sharp tools, which pose risks to workers. By automating these processes, the risk of injury is significantly reduced, creating a safer working environment. This is particularly important for businesses that prioritize the well-being of their employees and strive to maintain a safe and healthy workplace.

The Industrial Button Machine has proven to be a valuable asset in the realm of large-scale button production. Its efficiency, precision, cost-effectiveness, scalability, quality control, environmental benefits, and safety features make it an ideal choice for businesses looking to optimize their production processes. As the demand for high-quality buttons continues to grow, the Rectangle Button Maker stands out as a key tool in meeting these challenges and ensuring the success of button manufacturing operations.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语