Generally, the button feeding machine is a machine adapted for feeding shank type buttons sequentially into a sewing position. In general, the feed-through mechanism is intended to be relatively simple to maintain and low-cost. Moreover, it is not necessary for the machine operator to align the button holes. The machine can be quickly installed on an existing button sewing machine.

In order to feed the button, the feeding machine comprises a hopper and a chute. The hopper holds the shanks of the buttons, which are then pushed along the chute. The chute is arranged so that the shanks of the buttons are positioned to one side of the chute. The button feeding machine also comprises a presser foot with a channel leading into the chute. The button is moved to the sewing position when the presser foot is lifted.

The shanks of the buttons are arranged to engage the chute contour to extend the shanks to the side of the chute. This does not interfere with the natural gravitational throw of the shanks. However, the engagement of the shanks does not prevent the buttons from backing up. In addition, the shanks are not subjected to sufficient force to sever the thread connecting the buttons to the sewing machine.

The chute is positioned adjacent the discharge opening in the hopper. The ram arm has one end coupled to the oscillatory drive means. The other end is connected to the push arm. The push arm is connected to the base of the button feeding machine. The ram arm has a spring biased finger for engaging the button shank.

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Web Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Product Search

Exit Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features ...

View this series of products

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features high speed: ...

View this series of products

Computer tape cutting machine (cold, hot infrared) JM-120HLR

Fully automatic cutting, simple operation, wide application range and high cutting quality. Features high speed: It can cut 70~90 pieces p...

View this series of products

Industry News

Home / News / Industry News / The button feeding machine feeding shank type buttons sequentially into a sewing position

The button feeding machine feeding shank type buttons sequentially into a sewing position

PREV:Ball button feeders are commonly used in a variety of industriesNEXT:Using ultrasonic cutting machines has many benefits

Recommended Products

-

Computer tape cutting machine (cold knife) JM-120L

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

-

Computer tape cutting machine (rounded corners) JM-120R

Fully automatic cutting, simple operation, wide application range and high cutting quality. It ca...

-

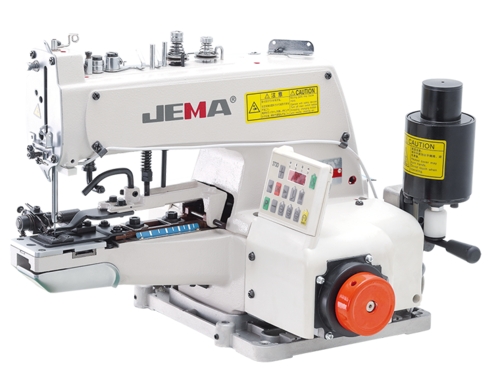

Button sewing machine JM-2373

Features Quickly adapt to a variety of sewing requirements. Corresponding to the changes in sewing...

-

Button sewing machine JM-377

Features It is mainly used for sewing flat buttons with two holes or four holes. If attac...

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

©2021 Taizhou JEMA Sewing Machine Co., Ltd. Custom Elastic Tape Cutting Machine Manufacturers

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语