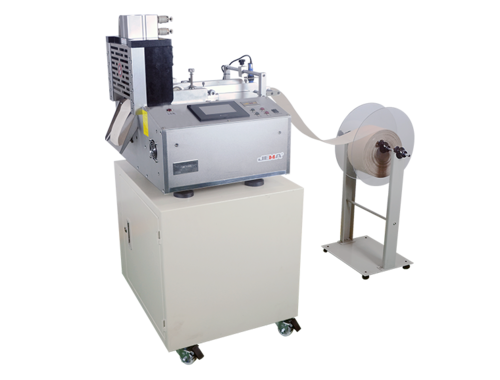

A rounded corners tape cutting machine is a specialized tool that is designed to cut adhesive tape, such as masking tape or duct tape, with rounded corners. This type of cutting machine is commonly used in the packaging industry, where it is necessary to cut large quantities of tape with a consistent and precise shape.

The machine typically consists of a cutting blade that is mounted on a moveable arm, which is controlled by a motor or manual lever. The tape is fed into the machine, and the blade is moved along the length of the tape to cut it into the desired length and shape. The rounded corner shape is achieved through the use of a cutting die, which is a specialized tool that is designed to produce a specific shape.

Rounded corners tape cutting machines are available in a range of sizes and capacities, from small tabletop models to larger industrial machines that can handle large rolls of tape. They can also be equipped with additional features, such as automatic feeders and digital controls, to improve their efficiency and precision.

Proper maintenance of a rounded corners tape cutting machine involves regular cleaning and lubrication to ensure that it is operating smoothly and accurately. The blade should be kept sharp and free of debris to ensure clean and precise cuts, and the cutting die should be inspected regularly for signs of wear or damage. Any issues should be addressed immediately to ensure the continued safe and efficient operation of the machine.

The rounded corners tape cutting machine is a special tool for cutting tape with rounded corners

PREV:What is the cutting mechanism of a computerized tape cutting machine?NEXT:Do you really know the Fabric saving machine (fixed/flexible long handle) JM-B11?

Recommended Products

-

Computer tape cutting machine (cold knife) JM-110L

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

-

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and...

-

Computerized tape cutting machine (hot knife) distribution tape device JM-120H / 300M

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

-

Computerized tape cutting machine (cold knife) JM-130L

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语