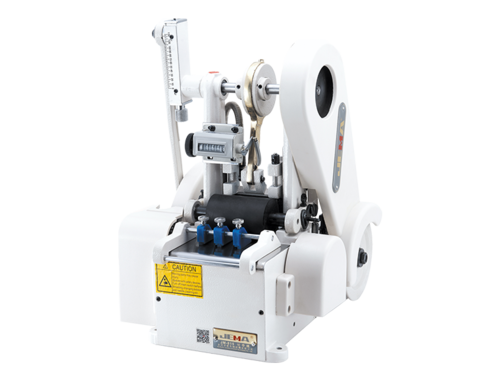

The Computer Tape Cutting Machine (Cold, Hot Infrared) is a marvel of modern engineering, representing the epitome of precision and efficiency in the domain of tape cutting technology. This ingenious machine, equipped with both cold and hot infrared cutting capabilities, has revolutionized tape cutting processes across various industries. In this comprehensive insight, we delve into the world of the Computer Tape Cutting Machine (Cold, Hot Infrared), exploring its design, functionality, and the transformative impact it has on tape cutting operations.

The Computer Tape Cutting Machine (Cold, Hot Infrared) operates at the forefront of tape cutting technology, integrating cold and hot infrared cutting mechanisms. The cold cutting method is ideal for materials sensitive to high temperatures, ensuring a clean and precise cut without any thermal damage. On the other hand, the hot infrared cutting method is efficient for cutting various materials swiftly and accurately, enhancing the overall versatility of the machine.

At the core of its functionality, the Computer Tape Cutting Machine (Cold, Hot Infrared) houses advanced sensors and computer-controlled mechanisms. These components work in perfect synchronization to detect the type of material and adjust the cutting method accordingly. This ensures optimal results for a wide range of materials, from delicate tapes to more robust substrates.

One of the primary advantages of the Computer Tape Cutting Machine (Cold, Hot Infrared) is its precision. The integration of cold and hot infrared cutting methods allows for highly accurate cuts, regardless of the material's properties. The machine's ability to adapt to different materials and adjust the cutting mechanism accordingly ensures consistent precision in every cut.

Moreover, the Computer Tape Cutting Machine (Cold, Hot Infrared) operates with remarkable efficiency. The cold and hot infrared cutting methods are optimized to reduce waste and enhance productivity. The machine can process a high volume of tapes in a short amount of time, making it an indispensable tool for industries that require efficient and precise tape cutting operations.

In industries such as packaging, printing, and textiles, the Computer Tape Cutting Machine (Cold, Hot Infrared) finds widespread use. It serves as a linchpin in the production of adhesive tapes, labels, and various textile products. The versatility of this machine makes it an essential component in applications where precision and speed are paramount.

Furthermore, the adaptability of the Computer Tape Cutting Machine (Cold, Hot Infrared) is noteworthy. Its user-friendly interface allows for easy customization and configuration based on specific requirements. Operators can easily set parameters such as cut length, width, and cutting method, tailoring the machine to suit their unique needs.

Maintenance of the Computer Tape Cutting Machine (Cold, Hot Infrared) is streamlined, contributing to its long operational life and reliability. Regular maintenance procedures, coupled with the machine's robust construction, ensure that it can endure challenging operational conditions. This durability significantly reduces maintenance requirements and minimizes downtime, enhancing the overall productivity of the system.

The Computer Tape Cutting Machine (Cold, Hot Infrared) is a pinnacle of precision engineering, embodying efficiency, versatility, and adaptability. Its integral role in numerous industries, from packaging to textiles, underscores its significance in driving seamless tape cutting operations. As industries continue to evolve and demand higher levels of precision and efficiency, the Computer Tape Cutting Machine (Cold, Hot Infrared) stands as a beacon of innovation and excellence.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语