A tape cutting machine is a piece of equipment that cuts various types of tape. It can automatically feed the tape and process it for cutting once it has been set to a specific length. It is useful for packaging purposes because it can automatically process the feeding and cutting process. It can also be used for many other industrial applications. To make the process easier, tape cutting machines can be operated in manual or automatic modes. A tape cutter is an essential tool in any warehouse or production line.

Webbing cutter is a tape cutting machine

This webbing cutter is a simple machine for cutting various materials with its hot and cold operation features. It also features an electromechanical integrating device that automatically adjusts length data. The machine's design makes it user-friendly and ergonomic, and the length can be set for many straps and materials. It is mainly used to cut the webbing belt and zipper belt made of nylon and velcro. In addition, the webbing cutter can be applied for cutting various other types of straps, including rope, cord, hose, and other types of webbing.

The main features of this machine are: hot and cold cutting function, high and low cutting speed, and a built-in fuse to prevent overheating. It is also equipped with an ultra-large cooling fan to maintain a cool cutting temperature. The webbing cutter has a microcomputer control system that automatically cuts the material without leaving any burrs. The machine has a 500W motor that can deliver 110 pc/min and a high-performance cooling fan to disperse heat efficiently.

Another type of webbing cutter is the hot knife model. This machine uses a heat-melting technique to cut tapes. The hot knife seals the edges without fraying and has an adjustable temperature. The hot knife can cut various materials with varying thicknesses, including nylon and woven belts. This machine is easy to use, and has an automatic stop button to stop the cutter when the material reaches its end.

Fabric tape cutting machine is a fabric tape cutting machine

The Fabric tape cutting machine is a high-performance tape cutter that is designed for fabric, nylon, or webbing cutting. The machine cuts various strap materials such as nylon webbing, velcro, zipper, and sheet metal. It also seals the ends of the tape without fraying. This machine has a stepping motor that delivers high precision and speed. The machine comes with many program settings so that it can cut various types of strap materials.

The cold cutter is made of durable and high-quality steel that cuts materials neatly. The machine automatically adjusts the length and quantity of materials it will cut. It also features an auto-stop roll-end detection sensor. It also has a digital display that shows how much tape is cut off at any time. This machine cuts strip, Velcro, and small webbing. Moreover, it is compatible with a variety of fabrics, including polyester and lycra.

Fabric tape cutting machines are also available with automatic cutter. Automatic belt cutters cut fabric tape without heat seal. They can also cut nylon buckles and woven belts. Another benefit of the automatic belt cutter is the fact that it is capable of cutting different types of materials such as aluminum, polyester, nylon, PP, and PVC tube. The fabric tape cutting machine also has a memory function and good length settings. The machine also features auto-stop feature when the cutting process is complete.

Fabric tape cutting machine can automatically process tape feeding and cutting after setting the length

A fabric tape cutting machine is a powerful piece of machinery for processing various types of fabrics. This machine is usually used for the cutting of Velcro, foam, leather, and gift belts. It can automatically cut all types of materials, including PVC trademark, washing water, printed label, and other non-woven fabrics. The tape feeding and cutting process can be automatically controlled after setting the length.

A modern fabric tape cutting machine can process tapes in a variety of shapes and sizes, and is often programmed offline for greater efficiency. These machines can automatically calculate the "natural path" for tape laying over a contoured surface. They can process ply after ply, and can display fiber orientation of each course and predicted gaps between adjacent courses. Modern tape laying machines also feature computer-controlled valves to adjust the temperature proportionally to machine speed and feed length.

To ensure the safety of your fabrics while using a fabric tape cutting machine, you must make sure that the blade is set to the correct level for the type of material being cut. If your fabric tape cutting machine is unable to process thicker materials, you should set the blade to its lowest setting. Otherwise, the blade may get caught on the mat, resulting in misalignment.

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Web Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Product Search

Exit Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

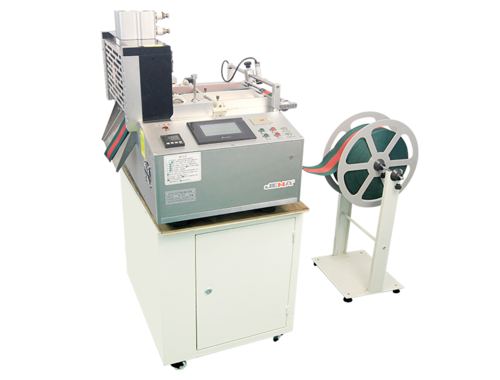

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features ...

View this series of products

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features high speed: ...

View this series of products

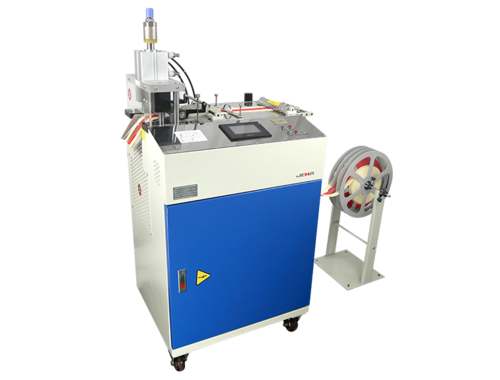

Computer tape cutting machine (cold, hot infrared) JM-120HLR

Fully automatic cutting, simple operation, wide application range and high cutting quality. Features high speed: It can cut 70~90 pieces p...

View this series of products

Industry News

What are the types of tape cutting machines?

PREV:What Is a Tape Cutting Machine?NEXT:The Elastic Tape Cutting Machine are available in a variety of models

Recommended Products

-

Computer tape cutting machine (cold, hot knife) JM-130LR

Fully automatic cutting, simple operation, wide application range and high cutting quality. Cold ...

-

Ultrasonic Computerized Tape Cutting Machine (Right Angle) JM-2100

Fully automatic cutting, easy operation. Wide application range, high cutting quality, smooth cut...

-

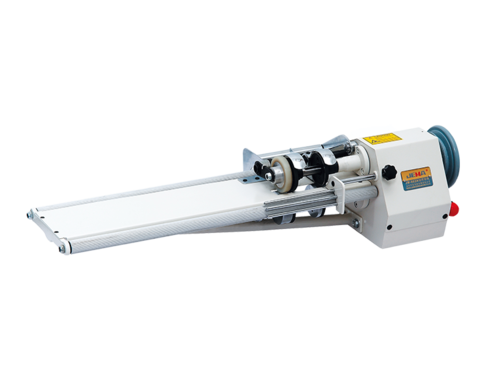

Cloth cutting machine JM-802A

special function: This sturdy machine is completely used for the manufacture of braided belts....

-

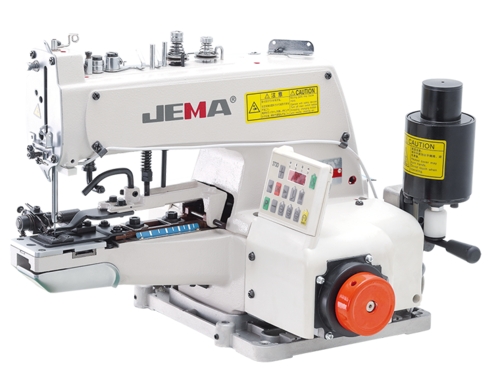

Button sewing machine JM-377

Features It is mainly used for sewing flat buttons with two holes or four holes. If attac...

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

©2021 Taizhou JEMA Sewing Machine Co., Ltd. Custom Elastic Tape Cutting Machine Manufacturers

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语