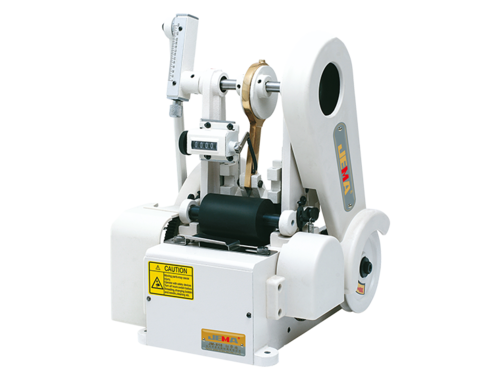

Sale Custom Automatic Tape Cutting Slitting Machine Supplier

In the dynamic landscape of the tape and label industry, innovation is the key to staying competitive. Auto tape cutting machines have emerged as a driving force behind this innovation, streamlining production processes and enhancing output quality. These machines are not just tools; they are catalysts for change, pushing the boundaries of what is possible in tape and label manufacturing. This article will explore the role of the auto tape cutting machines in propelling the industry forward, their current applications, and the potential they hold for future developments.

The tape and label industry is characterized by its need for high precision and efficiency. Sale Auto tape cutting machines have become indispensable in meeting these demands. By automating the cutting process, these machines reduce the risk of human error and increase the speed at which products can be manufactured. The integration of machines into production lines has led to a significant increase in productivity, allowing companies to meet the growing demands of their customers.

One of the primary benefits of the auto tape cutting machines is their ability to provide precise cuts. This precision is crucial in the tape and label industry, where the smaller of errors can result in product rejection. The machines are designed to cut materials with accuracy, ensuring that each piece is uniform and meets the required specifications. This level of precision not only improves the quality of the final product but also reduces waste, as fewer materials are lost due to cutting errors.

The efficiency gains offered by Custom Tape Slitting Machines are substantial. Manual cutting processes can be time-consuming and labor-intensive, whereas machines can perform the same tasks in a fraction of the time. This speed allows manufacturers to produce more products in less time, meeting tight deadlines and increasing overall output. The time saved can be redirected towards other aspects of the business, such as research and development, further driving innovation within the company.

As the industry moves towards greater automation and digitalization, auto tape cutting machines are becoming more integrated with other technologies. For example, they can be connected to computer systems that control the cutting process, allowing for real-time adjustments and monitoring. This integration not only improves the accuracy of the cutting process but also enables better tracking and management of production data. The data collected can be analyzed to identify trends and areas for improvement, further enhancing the efficiency of the manufacturing process.

Auto tape cutting machines contribute to sustainability in the tape and label industry by reducing waste and energy consumption. By reducing material waste, these machines help manufacturers adhere to environmental standards and reduce their carbon footprint. Additionally, the reduced labor requirements and increased efficiency result in cost savings, making machines an economically viable option for businesses.

The versatility of auto tape cutting machines is another factor driving their adoption in the industry. These machines can be programmed to cut a wide range of materials and sizes, allowing for greater customization in product offerings. This flexibility is particularly important in a market where consumer preferences are diverse and ever-changing. Manufacturers can quickly adapt their production lines to meet new demands, staying agile in a competitive market.

Looking ahead, the future of Automatic Tape Cutter Suppliers in the tape and label industry is promising. Advancements in technology will likely result in even more sophisticated machines capable of handling complex cutting patterns and materials. The development of smart auto tape cutting machines that can learn from past operations and self-optimize will further enhance efficiency and precision.

In conclusion, auto tape cutting machines are a testament to the innovation driving the tape and label industry forward. Their ability to provide precision, efficiency, and customization is transforming the way products are manufactured. As technology continues to evolve, auto tape cutting machines will play an increasingly important role in shaping the future of this dynamic industry.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语

.png?imageView2/2/w/500/h/500/format/jp2/q/100)