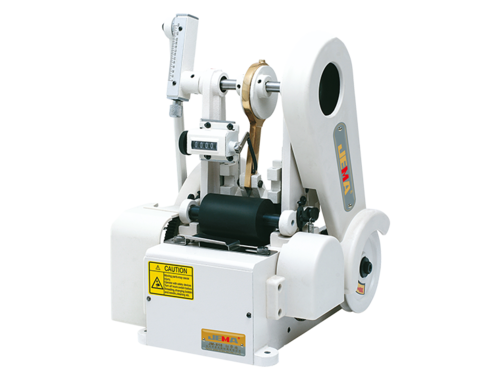

China Wholesale Auto Adhesive Tape Cutter Slitting Cutting Machine Factory

The tape and label industry has undergone a significant transformation in recent years, with the advent of advanced machinery that has revolutionized production processes. Among these innovations, the auto tape cutting machine stands out as a pivotal piece of equipment that has redefined efficiency and precision in manufacturing. This article will discuss the role of the China auto tape cutting machines in the modern manufacturing environment, highlighting their impact on productivity, quality, and innovation.

The auto tape cutting machine has become a staple in the tape and label industry due to its ability to automate the cutting process. This machine's introduction has reduced the reliance on manual labor, which was previously prone to human error and inconsistent results. The machine's precision-cutting capabilities have not only improved the quality of finished products but also increased the speed at which they are produced.

One of the primary roles of the auto tape cutting machine is to enhance efficiency and precision in the manufacturing process. By automating the cutting of tape and labels, these machines ensure that each piece is cut to the exact specifications required, without the variability that comes with manual cutting. This consistency is crucial for maintaining brand standards and ensuring that products meet the expectations of consumers.

The role of the auto tape cutting machines extends beyond mere cutting; they also play a significant part in quality control. With the ability to cut materials with high accuracy, these machines help to reduce waste and reduce the number of defective products. This results in cost savings for manufacturers and a better final product for end-users.

Another role that auto tape cutting machines play is in the realm of customization. As consumer demands for personalized products grow, the ability to quickly and accurately cut materials to specific dimensions becomes increasingly important. They can be programmed to cut a variety of shapes and sizes, allowing manufacturers to offer a wide range of products to meet diverse market needs.

The role of Wholesale Adhesive Tape Slittings is not limited to standalone operations; they are also integral to the integration of other technologies in the manufacturing process. For instance, these machines can be connected to digital design software, allowing for a seamless transition from design to production. This integration enables manufacturers to respond quickly to market trends and customer requests, further solidifying the machine's role in the industry.

In today's environmentally conscious world, the role of auto tape cutting machines in sustainability cannot be overlooked. By reducing waste through precise cutting, these machines contribute to the overall sustainability efforts of the tape and label industry. Manufacturers using it can boast reduced material usage and lower environmental impact, which is increasingly important to consumers and regulators alike.

As technology continues to advance, the role of auto tape cutting machines is set to expand. Future developments may include the incorporation of artificial intelligence and machine learning, which could further improve the efficiency and accuracy of these machines. Additionally, advancements in materials and cutting technologies could allow it to handle a wider range of materials, broadening its applicability in the industry.

The Auto Tape Cutter Factory has become an indispensable part of the tape and label industry, playing a multifaceted role in efficiency, quality control, customization, and sustainability. As the industry continues to evolve, its role is likely to grow, with ongoing technological advancements promising even greater capabilities. Manufacturers who embrace this technology are well-positioned to meet the challenges of the future, ensuring that the auto tape cutting machine remains at the forefront of innovation in the tape and label industry.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语