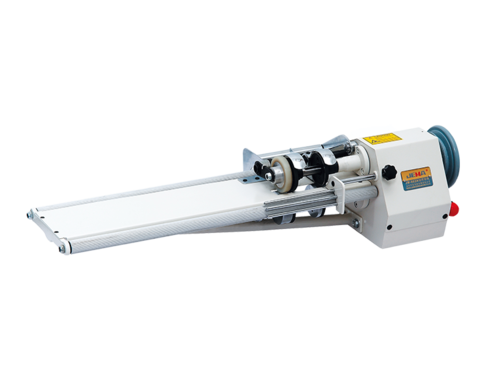

Computer tape cutting machine (cold knife) JM-120L

Fully automatic cutting, simple operation, wide application range, high cutting quality, c...

In the fast-paced world of garment manufacturing, efficiency, precision, and speed are crucial. Among the many technological advancements reshaping this industry, the automatic buttonhole stitching machine stands out as a significant innovation. This advanced machine is transforming the production process, providing unmatched benefits in terms of quality, productivity, and cost-effectiveness.

The automatic buttonhole stitching machine is engineered to meet the demanding requirements of modern garment production. Unlike traditional sewing machines, this specialized equipment automates the buttonhole creation process, ensuring uniformity and accuracy with every stitch. Its features and durable design make it an indispensable tool for manufacturers aiming to enhance their operations and deliver products.

One of the primary advantages of the automatic buttonhole stitching machine is its capability to produce consistent buttonholes rapidly. Manual buttonhole creation is often slow and susceptible to errors, but the automatic buttonhole stitching machine eliminates these issues by automating the task. This automation not only enhances the visual appeal of garments but also reduces the likelihood of defects, to higher customer satisfaction and fewer returns.

Efficiency is a hallmark of the automatic buttonhole stitching machine. By significantly decreasing the time needed to create buttonholes, manufacturers can boost their production rates. This increased efficiency is vital in a competitive industry where meeting tight deadlines is essential. The automatic buttonhole stitching machine enables manufacturers to produce more garments in less time, allowing them to respond swiftly to market trends and consumer demands.

The automatic buttonhole stitching machine is also highly versatile. It can handle a variety of fabrics, from delicate silks to sturdy denims, making it suitable for a wide range of garments. This flexibility is particularly valuable for manufacturers producing diverse clothing lines and requiring a machine that can accommodate different materials. Additionally, the automatic buttonhole stitching machine can create various buttonhole styles, such as keyhole, round, and straight, further enhancing its versatility.

Cost savings are another significant benefit offered by the automatic buttonhole stitching machine. By automating the buttonhole creation process, manufacturers can reduce their reliance on skilled labor, which can be both expensive and scarce. The machine’s precision also minimizes material waste, as it consistently produces buttonholes without the need for rework. These savings can be substantial, especially for large-scale operations, and can help improve overall profitability.

For designers, the automatic buttonhole stitching machine opens up new avenues for creativity and innovation. Its precise stitching capabilities allow designers to experiment with intricate and complex buttonhole designs that would be challenging to achieve manually. This ability to innovate leads to the creation of unique and distinctive garments that stand out in the competitive fashion market. The machine’s capacity to execute these designs flawlessly ensures that the final product meets the standards of quality and craftsmanship.

As sustainability becomes increasingly important in the fashion industry, the automatic buttonhole stitching machine supports eco-friendly practices. Its efficiency and precision reduce material waste, contributing to more sustainable manufacturing processes. Furthermore, the machine can work with a variety of sustainable and recycled fabrics, supporting the industry’s shift towards environmentally conscious production. By minimizing waste and accommodating eco-friendly materials, the automatic buttonhole stitching machine helps manufacturers reduce their environmental impact.

The future of garment manufacturing is bright with ongoing technological advancements, and the automatic buttonhole stitching machine is at the forefront of this evolution. Manufacturers are increasingly investing in these machines to stay competitive and meet the demands of a rapidly changing market. As technology continues to progress, we can expect even more sophisticated and efficient automatic buttonhole stitching machines that further enhance productivity and quality in garment production.

In conclusion, the automatic buttonhole stitching machine is a transformative tool that is revolutionizing the garment industry. Its ability to produce precise, uniform buttonholes quickly, handle a variety of fabrics, and reduce production costs makes it an invaluable asset for manufacturers. By enabling designers to innovate and supporting sustainable practices, the automatic buttonhole stitching machine is setting new standards in quality and efficiency.

Fully automatic cutting, simple operation, wide application range, high cutting quality, c...

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

special function: This sturdy machine is completely used for the manufacture of braided belts....

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...