Computer tape cutting machine (hot knife) JM-120H

Fully automatic cutting, simple operation, wide application range, high cutting quality, c...

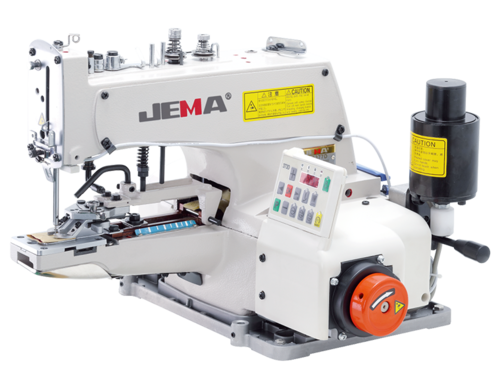

In the highly competitive world of garment manufacturing, efficiency, precision, and speed are paramount. Among the many technological advancements driving this industry forward, the industrial button hole sewing machine has emerged as a game-changer. This sophisticated piece of equipment is revolutionizing the production process, offering unparalleled benefits in terms of quality and productivity.

The industrial button hole sewing machine is designed to meet the rigorous demands of large-scale garment production. Unlike traditional sewing machines, this specialized machine automates the creation of buttonholes, ensuring consistency and precision with every stitch. Its advanced features and robust construction make it an essential tool for manufacturers looking to enhance their operations and deliver high-quality products.

One of the key advantages of the industrial button hole sewing machine is its ability to produce uniform buttonholes at high speed. In manual sewing processes, creating buttonholes can be time-consuming and prone to errors. The industrial button hole sewing machine eliminates these issues by automating the task, resulting in buttonholes every time. This automation not only improves the aesthetic appeal of garments but also reduces the risk of defects, to higher customer satisfaction.

Efficiency is another significant benefit offered by the industrial button hole sewing machine. By drastically reducing the time needed to create buttonholes, manufacturers can increase their production rates. This efficiency is crucial in a fast-paced industry where meeting deadlines is essential. With the industrial button hole sewing machine, manufacturers can produce more garments in less time, allowing them to respond quickly to market demands and fashion trends.

Versatility is also a hallmark of the industrial button hole sewing machine. It is capable of handling a wide range of fabrics, from delicate silks to sturdy denims, making it suitable for various garment types. This adaptability is particularly important for manufacturers who produce diverse clothing lines and need a machine that can accommodate different materials. Furthermore, the industrial button hole sewing machine can create various styles of buttonholes, including keyhole, round, and straight, adding to its versatility.

The industrial button hole sewing machine also offers significant cost savings for garment manufacturers. By automating the buttonhole creation process, companies can reduce their dependence on skilled labor, which can be costly and in short supply. Additionally, the machine’s precision minimizes material waste, as it produces buttonholes without the need for rework. These savings can be substantial, particularly for large-scale operations, and can help improve overall profitability.

For designers, the industrial button hole sewing machine opens up new possibilities for creativity and innovation. Its precise stitching capabilities allow designers to experiment with intricate and complex buttonhole designs that would be difficult to achieve manually. This flexibility enables the creation of unique and distinctive garments that stand out in the competitive fashion market. The machine’s ability to execute these designs flawlessly ensures that the final product meets the standards of quality and craftsmanship.

As the fashion industry places increasing emphasis on sustainability, the industrial button hole sewing machine plays a role in promoting eco-friendly practices. Its efficiency and precision reduce material waste, contributing to more sustainable production processes. Moreover, the machine can work with a variety of sustainable and recycled fabrics, supporting the industry’s shift towards environmentally conscious manufacturing. By minimizing waste and accommodating eco-friendly materials, the industrial button hole sewing machine helps manufacturers reduce their environmental footprint.

The future of garment manufacturing looks promising with continuous technological advancements, and the industrial button hole sewing machine is at the forefront of this progress. Manufacturers are investing in these machines to stay competitive and meet the demands of a rapidly evolving market. As technology continues to advance, we can expect even more sophisticated and efficient industrial button hole sewing machines that further enhance productivity and quality in garment production.

Fully automatic cutting, simple operation, wide application range, high cutting quality, c...

.png?imageView2/2/w/500/h/500/format/jp2/q/100)

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

Features Quickly adapt to a variety of sewing requirements. Corresponding to the changes in sewing...

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...