In the world of manufacturing, precision and efficiency are pivotal. Enter the

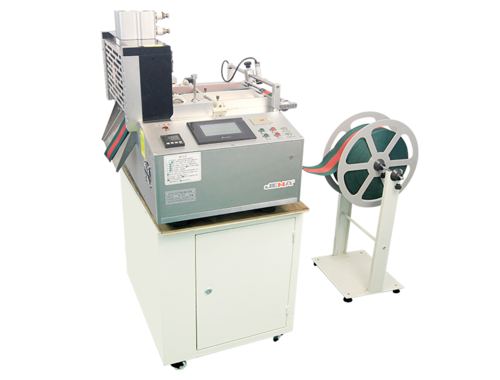

Tape Cutting Machines equipped with Cold and Hot Knife technology, revolutionizing the cutting process across industries and setting new standards for accuracy and versatility.

The dual capability of these cutting machines, incorporating both cold and hot knife functionalities, marks a significant advancement in cutting technology. Cold knife cutting involves a non-heated blade or laser, ensuring precise cuts without generating heat, while the hot knife method employs heat to seal edges, particularly beneficial for materials prone to fraying or unraveling.

Industries reliant on precise and tailored cutting processes, such as textiles, packaging, and automotive, have swiftly integrated these cutting machines into their operations. The incorporation of cold and hot knife functionalities offers unprecedented flexibility, catering to diverse material requirements and cutting specifications.

The precision and versatility of these machines have garnered praise from manufacturers seeking to optimize their production lines. "The Tape Cutting Machines with Cold and Hot Knife technology have been a game-changer for us," expressed Rachel Nguyen, a production manager. "They've streamlined our operations, ensuring precise cuts across various materials and saving us both time and resources."

One of the remarkable features of these cutting machines is their adaptability to a wide spectrum of materials. From tapes and fabrics to foams and films, the cold and hot knife functionalities ensure that each material receives the optimal cutting treatment, preserving quality and minimizing waste.

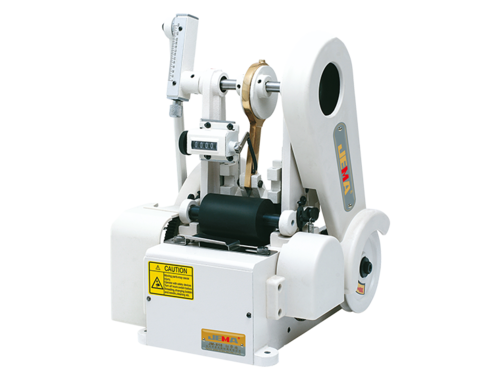

Moreover, these machines offer not just precision but also speed, revolutionizing production processes. The automated nature of the cutting process reduces human error, resulting in consistent and high-quality outputs, thereby significantly enhancing overall productivity.

The integration of Tape Cutting Machines with dual cold and hot knife capabilities isn't limited to large-scale manufacturing units. Small businesses and specialized workshops have also recognized the potential of these technologies in enhancing their craftsmanship and optimizing production processes.

Furthermore, these cutting machines align with sustainability goals by minimizing material waste. Their precision cutting ensures optimal utilization of materials, reducing scraps and enhancing resource efficiency, a factor that resonates profoundly with environmentally conscious industries.

The impact of these cutting machines extends beyond their immediate application in manufacturing. Their precision and adaptability have sparked innovative uses in sectors such as fashion design, automotive engineering, and medical device manufacturing, showcasing their versatility across diverse fields.

As industries evolve, the advancements in Tape Cutting Machines with Cold and Hot Knife technology continue to redefine manufacturing processes. Their ability to offer tailored cutting solutions while maintaining a focus on efficiency and quality positions them as indispensable tools across various sectors.

In a landscape where precision and adaptability are paramount, these cutting machines epitomize the synergy of technology and innovation, heralding a future where manufacturing processes are optimized to deliver superior quality and efficiency. As industries embrace these advancements, the impact of Tape Cutting Machines with dual cold and hot knife capabilities on manufacturing practices is poised to be a driving force in shaping the industry landscape.