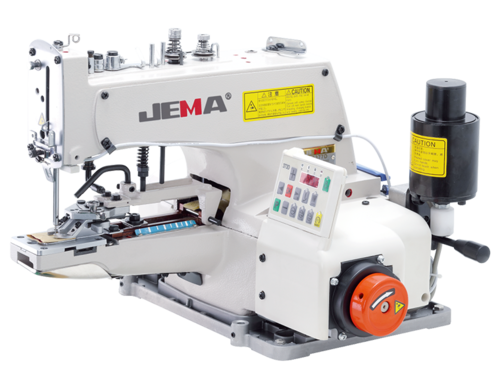

In the realm of garment production, a new era of efficiency and precision has emerged with the introduction of

High-Speed Computer Direct-Drive Button Sewing Machines. These state-of-the-art machines have swiftly become a cornerstone in the garment manufacturing industry, revolutionizing the process of attaching buttons with unparalleled accuracy and speed.

The advent of these button sewing machines represents a significant leap in technology. Equipped with advanced computer-controlled mechanisms and direct-drive systems, these machines offer unparalleled precision in attaching buttons to garments, catering to the demanding requirements of the fashion and textile industries.

The high-speed functionality of these machines has been a game-changer for manufacturers seeking to optimize their production lines. The precision and efficiency they offer have significantly reduced production times while ensuring consistent and flawless button attachment, marking a remarkable advancement in garment manufacturing technology.

Garment manufacturers have enthusiastically embraced these button sewing machines, recognizing their potential to streamline operations and enhance productivity. "The High-Speed Computer Direct-Drive Button Sewing Machines have transformed our production process," shared Emma Davis, a garment factory owner. "Their speed and accuracy have elevated the quality of our garments while allowing us to meet demanding deadlines."

One of the standout features of these machines is their ability to handle a diverse range of buttons and fabrics with precision. From delicate fabrics to heavier materials, these machines can seamlessly attach various types and sizes of buttons, ensuring secure fastening without compromising on quality.

Moreover, the integration of computer-controlled systems in these sewing machines minimizes human error, ensuring consistent and high-quality button attachment. The direct-drive technology enhances control and responsiveness, resulting in smoother and more accurate sewing operations.

The impact of these high-speed button sewing machines isn't confined to large-scale garment factories alone. Small-scale designers and tailors have also embraced this technology, recognizing its potential to enhance their craftsmanship and accelerate their production processes.

Furthermore, these machines align with sustainability goals by optimizing material usage and reducing waste. Their precision in attaching buttons minimizes material wastage and ensures optimal utilization, resonating with environmentally conscious practices increasingly prevalent in the fashion industry.

The adoption of High-Speed Computer Direct-Drive Button Sewing Machines has sparked innovation in garment design and production. Their speed and precision have enabled designers to explore intricate button arrangements and creative embellishments, pushing the boundaries of garment aesthetics.

As the garment manufacturing landscape evolves, the technological advancements in button sewing machines continue to drive the industry toward greater efficiency and precision. Their capacity to redefine production processes while maintaining a focus on quality and speed positions them as indispensable tools in garment manufacturing.

In a world where precision and efficiency are paramount, these High-Speed Computer Direct-Drive Button Sewing Machines symbolize the convergence of technology and innovation, heralding a future where garment production is optimized for superior quality and accelerated timelines. As the industry embraces these advancements, the impact of these machines on garment manufacturing practices is poised to set new benchmarks in efficiency and quality standards.