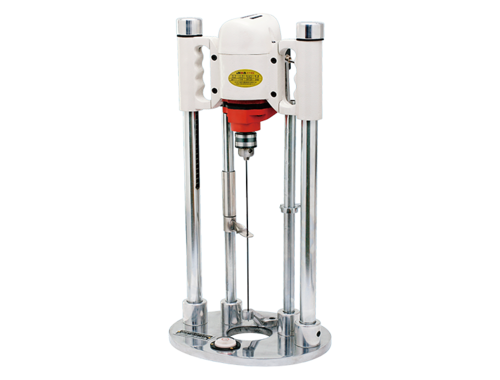

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and...

In the world of manufacturing, efficiency, and precision are key to success. One technology that has revolutionized the industry is the Ultrasonic Cutting Machine. This advanced piece of equipment has become an indispensable tool in many production lines, offering unparalleled speed, accuracy, and versatility. In this article, we will explore how Sale Ultrasonic Cutting Machines streamline production lines, enhancing productivity and quality.

Ultrasonic Cutting Machines utilize high-frequency vibrations to cut materials with exceptional precision. These machines operate at frequencies above the audible range for humans, typically between 20 kHz and 40 kHz. The ultrasonic vibrations are transferred to a cutting tool, which then cuts through materials with reduced resistance. This technology is particularly effective for cutting delicate or heat-sensitive materials without causing damage or distortion.

Streamlining Production with Ultrasonic Cutting Machines. One of the primary benefits of it is its ability to increase production line efficiency. These machines can cut materials at a much faster rate than traditional cutting methods, such as blade or laser cutting. This speed allows for a significant reduction in production time, resulting in higher output and improved profitability.

Ultrasonic Cutting Machines offer unparalleled precision, which is crucial in industries where accuracy is paramount. The high-frequency vibrations ensure that cuts are clean and consistent, reducing the need for secondary finishing processes. This precision also reduces material waste, as the cuts are made with exact measurements, resulting in cost savings.

The versatility of Ultrasonic Cutting Machines is another factor that contributes to their ability to streamline production lines. These machines can cut a wide range of materials, including textiles, plastics, rubber, and even metals. This adaptability allows manufacturers to use a single machine for multiple applications, reducing the need for additional equipment and simplifying the production process.

By reducing the cutting tolerance and ensuring that each cut is made with precision, Ultrasonic Cutting Machines significantly reduce material waste. This not only saves on material costs but also contributes to a more sustainable production process, as less material is discarded.

The consistent and precise cuts made by Custom Ultrasonic Label Cutting Machines result in improved quality control. With fewer defects and inconsistencies in the final product, manufacturers can maintain higher standards of quality, which is essential for customer satisfaction and brand reputation.

Ultrasonic Cutting Machines are known for their low maintenance requirements. The absence of moving parts that are subject to wear and tear, such as belts and gears, means that these machines require less frequent servicing. This reduces maintenance costs and downtime, further streamlining the production line.

The operation of Ultrasonic Cutting Machines is safer than traditional cutting methods. There is no risk of sharp blades or hot surfaces, which can cause injuries. Additionally, the absence of sparks and flames makes these machines suitable for use in environments where safety is a concern.

They are energy-efficient, consuming less power than other cutting technologies. This not only reduces energy costs but also aligns with the growing demand for environmentally friendly manufacturing processes.

The operation of Ultrasonic Cutting Machines is quieter than traditional cutting methods, which can be particularly beneficial in noise-sensitive environments. This reduction in noise pollution contributes to a more comfortable working environment for employees and can also help to meet noise regulations in certain industries.

Many Ultrasonic Cutting Table Suppliers can be customized to meet specific production needs, and they are often compatible with automation systems. This allows for the integration of these machines into automated production lines, further enhancing efficiency and reducing the need for manual labor.

Ultrasonic Cutting Machines have proven to be a game-changer in the manufacturing industry. By offering increased efficiency, precision, versatility, and a range of other benefits, these machines have the power to streamline production lines and improve overall manufacturing processes. As technology continues to advance, the role of Ultrasonic Cutting Machines in streamlining production lines is likely to become even more significant, driving innovation and efficiency in manufacturing worldwide.

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and...

Features The JM-60/70 miniature cutting machine is suitable for cutting curves, small arcs and...

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...

Features This machine is one of the indispensable special equipments in garment production. It...