Computerized tape cutting machine (hot knife) distribution tape device JM-120H / 300M

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

The apparel industry is one of the competitive sectors in the global market, with constant pressure to innovate and improve production processes. One significant technological advancement that has reshaped the way garments are produced is the Ultrasonic Cutting Machine. This cutting-edge equipment has not only transformed the way fabrics are cut but has also significantly impacted the overall efficiency and quality of apparel production. In this article, we will delve into the profound effects of China Ultrasonic Cutting Machines on the apparel industry, examining their role in streamlining operations, enhancing product quality, and reducing waste.

Ultrasonic Cutting Machines have become a cornerstone in the apparel production process due to their ability to cut various materials with precision and speed. These machines use high-frequency vibrations to cut through fabrics, eliminating the need for traditional cutting tools like blades or scissors. The use of it has several benefits that have a direct impact on apparel production.

One of the primary advantages of Ultrasonic Cutting Machines is their ability to provide precise cuts. This precision is crucial in the apparel industry, where even a slighter error can result in costly mistakes. By using Ultrasonic Cutting Machines, manufacturers can ensure that every piece of fabric is cut to the exact specifications, reducing the risk of errors and rework. This precision also allows for the creation of intricate designs and patterns that would be difficult or impossible to achieve with traditional cutting methods.

The speed at which Ultrasonic Cutting Machines operate is another significant benefit for the apparel industry. These machines can cut through multiple layers of fabric simultaneously, significantly reducing the time it takes to produce a single garment. This increased speed not only shortens production times but also allows manufacturers to meet higher demand with fewer machines, ultimately saving on costs and resources.

Ultrasonic Cutting Machines also contribute to reducing material waste in the apparel industry. Traditional cutting methods often leave behind a significant amount of fabric scraps, which can be costly and environmentally harmful. However, Wholesale Ultrasonic Rubber Cutters produce reduced waste due to their precision and the ability to cut complex shapes without the need for additional trimming. This reduction in waste not only saves money but also aligns with the growing trend of sustainability in the fashion industry.

The use of Ultrasonic Cutting Machines The impact of Ultrasonic Cutting Machines on apparel production is undeniable. They have transformed the way garments are made, offering a range of benefits that include increased precision, speed, reduced waste, improved quality, versatility, enhanced safety, cost-effectiveness, and environmental considerations. As the apparel industry continues to evolve, the adoption of Ultrasonic Cutting Machines will likely become even more widespread, further shaping the future of fashion manufacturing. improved quality and consistency in apparel production. Since these machines can cut through fabrics with minimal fraying or distortion, the resulting garments have a more professional and polished appearance. This consistency in quality is essential for maintaining brand reputation and customer satisfaction.

Ultrasonic Cutting Machines are not limited to cutting a single type of fabric. They can handle a wide range of materials, from delicate silks to heavy-duty canvas. This versatility allows manufacturers to produce a diverse range of products without the need for multiple cutting machines, further streamlining the production process.

Traditional cutting methods can be hazardous, with the risk of accidents and injuries from sharp blades and tools. Ultrasonic Slitting Factory, on the other hand, offer a safer alternative. The absence of sharp edges and the use of non-contact cutting methods reduce the risk of accidents, creating a safer working environment for employees.

The environmental impact of apparel production is a growing concern for both consumers and manufacturers. Ultrasonic Cutting Machines play a role in reducing this impact by reducing waste and energy consumption. The energy-efficient operation of these machines, coupled with the reduced waste, aligns with the industry's move towards more sustainable practices.

The impact of Ultrasonic Cutting Machines on apparel production is undeniable. They have transformed the way garments are made, offering a range of benefits that include increased precision, speed, reduced waste, improved quality, versatility, enhanced safety, cost-effectiveness, and environmental considerations. As the apparel industry continues to evolve, the adoption of Ultrasonic Cutting Machines will likely become even more widespread, further shaping the future of fashion manufacturing.

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

Features Quickly adapt to a variety of sewing requirements. Corresponding to the changes in sewing...

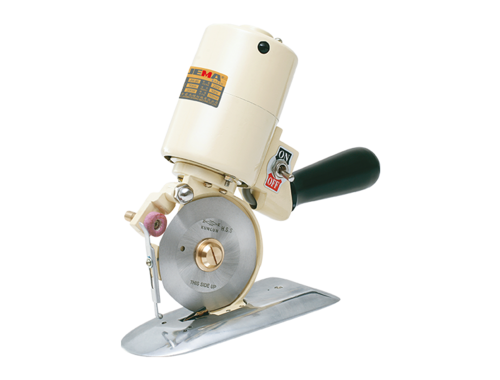

Features The JM-60/70 miniature cutting machine is suitable for cutting curves, small arc...

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...