Computer tape cutting machine (cold, hot) JM-110LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and...

In the ever-evolving world of fashion and textile manufacturing, advancements in technology continue to revolutionize traditional methods. One such innovation making significant waves is the automatic button hole sewer machine. This cutting-edge device is enhancing efficiency, precision, and productivity in sewing industries around the globe, heralding a new era in garment production.

The automatic button hole sewer machine is designed to streamline the process of creating buttonholes in garments, a task that was traditionally labor-intensive and time-consuming. By automating this process, manufacturers can significantly reduce production times and labor costs, to increased output and profitability. This is especially crucial in the highly competitive fashion industry, where speed and efficiency can make all the difference.

One of the standout features of the automatic button hole sewer machine is its precision. Each buttonhole is crafted to exact specifications, ensuring uniformity and high quality across all garments. This level of consistency is difficult to achieve with manual methods, where human error can to variations in size and placement. With the automatic button hole sewer machine, designers and manufacturers can be confident in the finished product’s quality, enhancing brand reputation and customer satisfaction.

Moreover, the automatic button hole sewer machine is equipped with advanced programming capabilities, allowing for a wide range of customization options. Users can easily adjust settings to create different styles of buttonholes, from simple straight stitches to more intricate patterns. This flexibility is invaluable for fashion designers looking to add unique touches to their creations without compromising on efficiency.

The speed at which the automatic button hole sewer machine operates is another game-changing factor. Traditional methods of sewing buttonholes are not only labor-intensive but also relatively slow, especially when dealing with large production runs. In contrast, the automatic button hole sewer machine can complete numerous buttonholes in a fraction of the time, significantly boosting productivity. This rapid pace is essential for meeting tight deadlines and fulfilling large orders in the fast-paced fashion industry.

In addition to speed and precision, the automatic button hole sewer machine offers significant labor savings. By automating the buttonhole sewing process, manufacturers can reallocate their workforce to other critical areas of production, optimizing overall efficiency. This reduction in manual labor also minimizes the risk of repetitive strain injuries among workers, promoting a healthier work environment.

The automatic button hole sewer machine is not just limited to large-scale manufacturers; it is also a valuable tool for small businesses and independent designers. For smaller operations, the ability to produce high-quality buttonholes quickly and efficiently can level the playing field, allowing them to compete with larger brands. The machine’s ease of use and programmable settings make it accessible to users with varying levels of expertise, from seasoned professionals to newcomers in the industry.

Sustainability is another important consideration in modern manufacturing, and the automatic button hole sewer machine contributes positively in this regard. By reducing waste and improving efficiency, it supports more sustainable production practices. Fewer resources are required to produce each garment, and the reduction in errors means less material is wasted. This aligns with the growing consumer demand for environmentally responsible products, helping brands to meet their sustainability goals.

The impact of the automatic button hole sewer machine is already being felt across the industry. Companies that have adopted this technology report significant improvements in production speed, quality, and cost-effectiveness. As word of its benefits spreads, more manufacturers are expected to follow suit, further transforming the landscape of garment production.

Innovation in the sewing industry is not new, but the introduction of the automatic button hole sewer machine represents a particularly significant leap forward. Its ability to combine speed, precision, and flexibility makes it a powerful tool for modern manufacturers. As technology continues to advance, we can expect even more sophisticated versions of this machine, further enhancing its capabilities and benefits.

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and...

Fully automatic cutting, simple operation, wide application range, high cutting quality, c...

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...

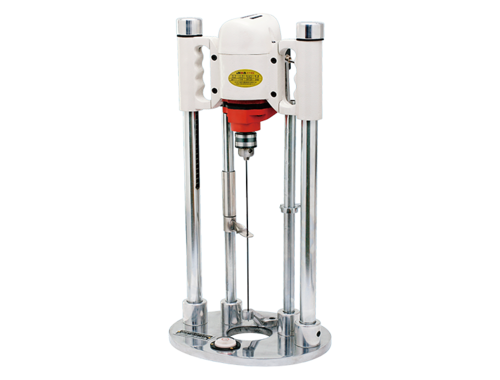

Features This machine is one of the indispensable special equipments in garment production. It...