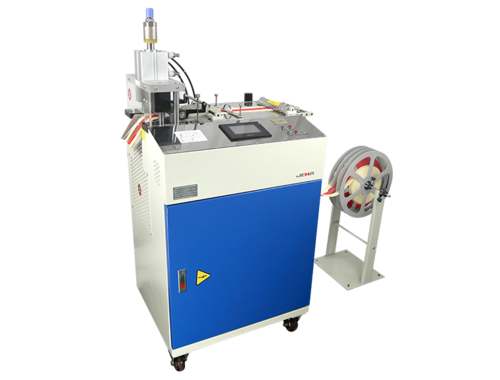

Multifunctional Computerized Tape Cutting Machine (Hot Knife) JM-150H

Fully automatic cutting, simple operation, wide application range, high cutting quality, smooth c...

In the fast-paced world of manufacturing, efficiency and productivity are key factors in meeting the demands of consumers and staying competitive in the market. Enter industrial button sewing machines, specialized equipment designed to streamline the process of attaching buttons to garments and textiles. With their advanced features, high-speed operation, and precision stitching capabilities, industrial button sewing machines are revolutionizing the way clothing and textile manufacturers produce garments, enhancing efficiency and quality in the production process.

At the heart of every garment lies the essential detail of buttons, and industrial button sewing machines play a crucial role in ensuring that these components are securely attached with precision and consistency. These machines are engineered to handle the rigorous demands of high-volume production, capable of sewing buttons onto a wide range of fabrics and materials quickly and accurately. Whether used in clothing factories, textile mills, or garment workshops, industrial button sewing machines offer manufacturers a reliable and efficient solution for automating the button attachment process.

One of the key features of industrial button sewing machines is their high-speed operation, which allows manufacturers to significantly increase their production output without sacrificing quality. Equipped with powerful motors and advanced stitching mechanisms, these machines can sew buttons onto garments at speeds far exceeding those achievable by manual sewing methods. This increased speed not only reduces production time but also enables manufacturers to fulfill large orders more quickly, helping to meet tight deadlines and customer demand.

Moreover, industrial button sewing machines are designed with precision and accuracy in mind, ensuring that buttons are attached securely and evenly to garments with each stitch. Many machines are equipped with adjustable settings and specialized stitching patterns that allow operators to customize the button attachment process to suit the specific requirements of different garments and materials. This precision stitching capability helps to ensure consistent quality across all products, reducing the risk of defects and rework in the manufacturing process.

In addition to their speed and precision, industrial button sewing machines offer a range of features and capabilities that enhance their versatility and usability in manufacturing environments. Many models come equipped with automatic button feeding systems, thread cutting mechanisms, and programmable controls that streamline the button attachment process and minimize operator intervention. Some machines even feature built-in sensors and diagnostic tools that detect and correct stitching errors in real-time, further improving efficiency and reducing downtime.

Furthermore, the adoption of industrial button sewing machines is part of a larger trend towards automation and digitization in the manufacturing industry. As manufacturers seek to improve efficiency, reduce labor costs, and enhance quality control, they are increasingly turning to automated solutions like industrial button sewing machines to streamline production processes. By automating repetitive and labor-intensive tasks, these machines free up human resources to focus on more skilled and value-added activities, driving overall productivity and competitiveness in the market.

Moreover, industrial button sewing machines are playing a crucial role in enabling manufacturers to meet the growing demand for custom and personalized garments. With their versatility and precision stitching capabilities, these machines allow manufacturers to easily attach buttons of different sizes, shapes, and styles to garments, offering greater flexibility in design and customization. This ability to quickly and efficiently produce custom garments helps manufacturers differentiate their products in the market and meet the unique preferences of consumers.

In conclusion, industrial button sewing machines are transforming the way clothing and textile manufacturers produce garments, enhancing efficiency, quality, and customization capabilities in the production process. With their high-speed operation, precision stitching, and automated features, these machines offer manufacturers a reliable and efficient solution for streamlining the button attachment process. As demand for custom and personalized garments continues to grow, industrial button sewing machines are poised to become indispensable tools for manufacturers seeking to stay competitive in the fast-paced world of fashion and textiles.

Fully automatic cutting, simple operation, wide application range, high cutting quality, smooth c...

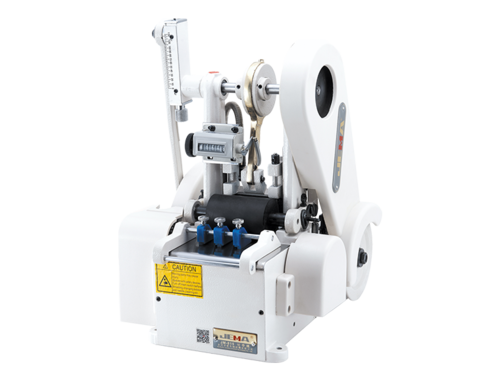

Fully automatic cutting, easy operation. Wide application range, high cutting quality, smooth cut...

Features It is suitable for shoes, hats, bags, and supporting equipment in clothing produ...

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...