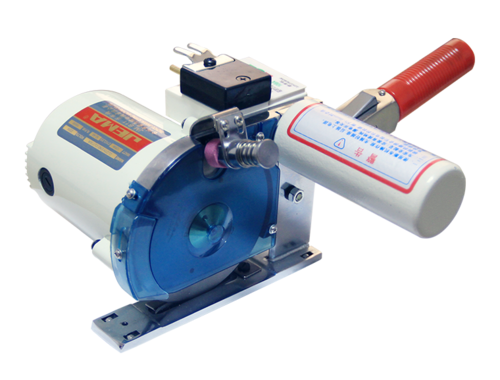

Computer tape cutting machine hot cutting knife (corner) JM-120HX

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and...

In the fast-paced environment of modern factories, efficiency, precision, and productivity are paramount. One technological advancement that has become essential in achieving these goals is the Button Feeding Machine. This innovative device has transformed the way buttons are applied in various manufacturing settings, particularly in the garment industry. Understanding the benefits of the Custom Button Feeding Machine provides insight into why it is increasingly becoming a staple in factories striving for operational excellence.

The primary benefit of the Button Feeding Machine is its ability to significantly enhance efficiency in the production process. Traditionally, attaching buttons to garments was a time-consuming manual task. Workers had to handle each button individually, which could slow down production and introduce variability. The Button Feeding Machine automates this process, allowing for continuous operation and drastically reducing the time required to complete button application. This increased efficiency enables factories to meet higher production demands and streamline their operations.

Precision and consistency are critical in garment manufacturing, where even small variations can impact the product's quality. The Button Feeding Machine excels in delivering precise and consistent button placement. Unlike manual methods, which are prone to human error, the machine ensures that each button is positioned accurately and attached securely. This consistency not only improves the overall appearance of the garments but also reduces the likelihood of defects and the need for rework, resulting in higher-quality products.

By automating the button application process, the Button Feeding Machine helps factories reduce labor costs. Manual buttoning requires significant human resources, which can be costly and challenging to manage. The machine's ability to handle this task efficiently means that fewer workers are needed for button application, allowing factories to allocate their workforce to other critical areas. This reduction in labor costs contributes to overall cost savings and enhances the factory's profitability.

The OEM Fully Automatic Snap Button Machine also contributes to a safer and more ergonomic work environment. Manual button application often involves repetitive motions that can result in strain and injuries among workers. By automating this task, the machine reduces the physical demands on employees, decreasing the risk of work-related musculoskeletal disorders. Additionally, with fewer workers involved in repetitive tasks, the factory environment becomes less physically taxing and more comfortable for employees.

Modern Button Feeding Machines are designed with versatility in mind. They can handle a variety of button sizes, types, and styles, making them suitable for different production needs. This flexibility is particularly beneficial in factories that produce a diverse range of garments. The machine can be easily adjusted to accommodate different button specifications, allowing factories to adapt quickly to changing design requirements and market trends.

The automation provided by the Button Feeding Machine also contributes to reduced material waste. Manual button application can result in higher rates of button loss or damage, resulting in wasted materials and increased production costs. The machine's efficiency and precision reduce such waste by ensuring that each button is used effectively and applied correctly. This reduction in waste not only helps the factory's bottom line but also supports more sustainable production practices.

Production speed is a crucial factor in meeting market demands and staying competitive. The Fabric Button Maker accelerates the button application process, allowing factories to produce garments at a faster rate. This increased speed enables factories to respond more quickly to customer orders and market trends, giving them a competitive edge in the fast-paced fashion industry.

In conclusion, the Button Feeding Machine offers a range of benefits that enhance the efficiency, precision, and overall performance of factory operations. From improving productivity and reducing labor costs to ensuring consistent quality and reducing waste, the machine plays a crucial role in modern manufacturing. Its versatility, adaptability, and impact on worker safety make it an indispensable tool for factories aiming to achieve operational excellence and maintain a competitive edge in the industry.

.png?imageView2/2/w/500/h/500/format/jp2/q/100)

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and...

.png?imageView2/2/w/500/h/500/format/jp2/q/100)

Fully automatic cutting, simple operation, wide application range, high cutting quality, smooth c...

special function: Need to cut fabrics in large quantities, such as cotton, wool, and wire mesh...

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...