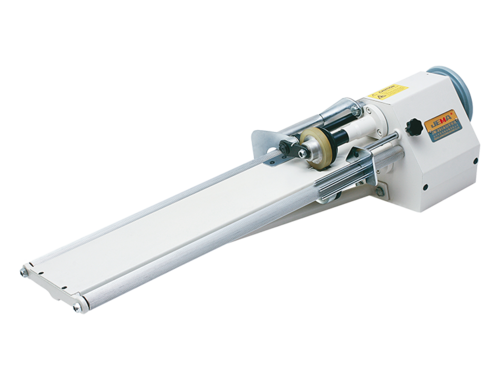

China Custom Fabric Button Press Feeding Snap Machine For Clothing Manufacturer

In the world of garment manufacturing, the assembly of buttons is a task that is often overlooked but is crucial to the product's quality and appearance. The Button Feeding Machine has emerged as an indispensable tool in this process, streamlining the installation of large quantities of buttons with precision and efficiency. This article delves into the significance of the China Button Feeding Machine, and its role in the garment industry.

The Button Feeding Machine is a specialized piece of equipment designed to automate the process of feeding buttons into sewing machines. This innovation has revolutionized the way buttons are attached to garments, reducing the time and labor required for this task. The machine's ability to handle large quantities of buttons is particularly beneficial for high-volume production lines, where speed and consistency are paramount.

One of the primary advantages of the Button Feeding Machine is its capacity to maintain a consistent feed rate. This consistency ensures that buttons are attached at a uniform pace, which is essential for maintaining the garment's aesthetic appeal. The machine's precision also reduces the risk of button misalignment or damage, which can occur when buttons are manually fed into a sewing machine.

The integration of the Button Feeding Machine into the production process has led to significant improvements in productivity. By automating the button-feeding process, manufacturers can increase the speed at which garments are produced without compromising on quality. This is particularly important in industries where quick turnaround times are necessary, such as fashion, where trends can change rapidly.

Moreover, the Button Feeding Machine's efficiency in handling large quantities of buttons also contributes to cost savings. The reduction in labor hours required for button installation translates to lower production costs, which can be passed on to consumers in the form of more competitive pricing. This cost-effectiveness is a key factor in the machine's widespread adoption across various sectors of the garment industry.

The Button Feeding Machine's versatility is another aspect that has contributed to its popularity. It is capable of handling a wide range of button sizes and types, making it suitable for use in the production of various garment types. This adaptability ensures that the machine can be utilized across different product lines, further enhancing its value to manufacturers.

In addition to its practical benefits, the Custom Snap Machine For Clothing also offers ergonomic advantages. Manual button feeding can be a labor-intensive task that requires workers to maintain a certain posture for extended periods. The use of it reduces the physical strain on workers, contributing to a safer and more comfortable work environment.

The Button Feeding Machine's impact on the garment industry extends beyond the production floor. Its ability to handle large quantities of buttons with precision has also influenced the design of garments. Designers can now incorporate more intricate button arrangements and patterns into their designs, knowing that they can accurately reproduce these details in the production process.

As technology continues to advance, the Button Feeding Machine is also evolving. Newer models are equipped with features such as programmable settings, which allow for even greater customization in the button-feeding process. This ongoing innovation ensures that it remains at the forefront of garment production technology.

In conclusion, the Fabric Button Press Manufacturer is a vital tool in the modern garment industry. Its ability to efficiently handle large quantities of buttons has transformed the way buttons are installed on garments, resulting in improvements in productivity, cost-effectiveness, and design possibilities. As the industry continues to evolve, the Button Feeding Machine will undoubtedly remain a cornerstone of garment production, ensuring that the humble button continues to play a significant role in the world of fashion.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语