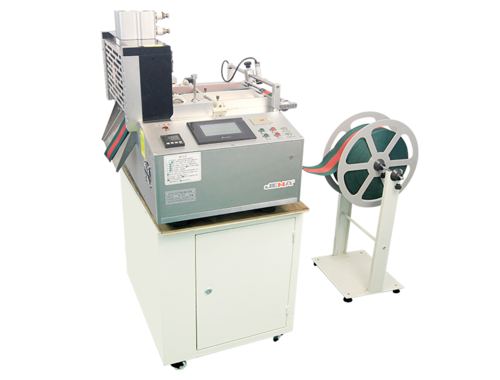

Elastic Tape Cutting Machine

An Elastic Tape Cutting Machine is a useful tool for cutting elastic tapes. It can be adjusted for length and precision cutting. Its maximum hot cutting temperature is 350°F, which guarantees high heat sealing efficiency. It is fully automated and can work at a maximum speed of 110 pieces per minute based on a 50 mm length of elastic tape. It can also be customized according to the desired length of elastic, ensuring high productivity.

Features

An elastic tape cutting machine is a piece of machinery that is used for cutting elastic tape. It features an AC motor that is accompanied with an inverter and an LCD touch panel for controlling the cutting process. Another important feature is the urging assembly, which is a pivotally supported arm that is mounted with an elastic body. The arm engages the elastic tape in the guide groove 25 through pressure. The arm also includes a slot 28a for passing the elastic tape.

Elastic tape cutting machines are available in various models, with each model able to cut different types of materials. Most machines have a counter that can be used to set the amount of tape to cut, and they also have an alarm to alert the user when the tape is tangled.

Applications

There are several applications for an elastic tape cutting machine. The main purpose of an elastic tape cutting machine is to cut the elastic tape. This machine can be used in different industries such as textile, packaging and garments. It has a high level of automation. This machine is able to cut and trim the elastic tape in a precise manner.

The machines feature adjustable lengths, precise cuts and accurate spacing. They are suitable for both single and multiple operators. In addition, they feature a bobbin-free design, which allows the user to use any size of core. The cut length is also accurate to within 0.08 inches.

Precision cutting length

For cutting woven, knitted, or braided elastics, precision cutting length machines are necessary. This type of cutting machine stretches the elastic tape to a length that will be uniform throughout the length. The edges of the tape are heated to melting temperature to ensure that there are no fraying edges. It is also suitable for cutting narrow fabric or webbings.

During cutting, it is necessary to follow the manufacturer's instructions closely. If there is a slight deviation from the blade, the material may end up being wasted. If it is too long or too short, the tape may tear or stretch prematurely.

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Web Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Product Search

Exit Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features ...

View this series of products

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features high speed: ...

View this series of products

Computer tape cutting machine (cold, hot infrared) JM-120HLR

Fully automatic cutting, simple operation, wide application range and high cutting quality. Features high speed: It can cut 70~90 pieces p...

View this series of products

Industry News

The features and applications of elastic tape cutting machine

PREV:The benefits of ultrasonic cutting machines are endlessNEXT:Elastic tape cutting machine is care free

Recommended Products

-

Computer tape cutting machine (cold knife) JM-110L

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

-

Computer tape cutting machine (cold knife infrared) JM-120HL

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

-

Computer tape cutting machine (cold, hot knife) JM-130LR

Fully automatic cutting, simple operation, wide application range and high cutting quality. Cold ...

-

Round knife cutting machine JM-100

Features The JM-60/70 miniature cutting machine is suitable for cutting curves, small arcs and...

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

©2021 Taizhou JEMA Sewing Machine Co., Ltd. Custom Elastic Tape Cutting Machine Manufacturers

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语