Ultrasonic cutting machines utilize high-frequency vibrations to cut materials. They are excellent for cutting welding and sealing materials, but they can also be used for cutting textile materials without tearing or fraying the edges. Various materials, including carpet, fleece, and Velcro, can be cut using an ultrasonic cutting machine.

This type of cutting machine is common in food processing plants. It has a built-in auto-cleaning system, which cleans the cutting blade when necessary. In addition, most ultrasonic cutting machines come with compatible software that helps set up the cutting operation. The software also accommodates new cut patterns instantly. Many machines also allow the user to reject defective products.

The ultrasonic cutting machine works by using a transducer to send high-frequency AC current to the cutting blade. This high-frequency current causes oscillations within the cutting blade, which help to heat and melt the material. The transducer can be adjusted for various levels of vibration to create the optimal cutting process.

An ultrasonic cutting machine is an efficient way to cut materials without the use of sharp edges or great pressure. The cutting edge is small, and there is no chance of chipping or breaking. This cutting method is particularly effective for materials that are viscous, frozen, or otherwise difficult to apply pressure.

Because of its fast and precise cutting capabilities, ultrasonic cutting machines can be used for many manufacturing processes. This type of machine works on soft and hard materials and is often used for textile manufacturing. It can cut non-woven fabrics, composite materials, and rubber, reducing waste and saving time. Ultrasonic cutting machines have a wide range of uses in the manufacturing industry, from food processing to electronics manufacturing.

The benefits of ultrasonic cutting machines are endless. This cutting method works by generating a series of microscopic vibrations in the cutting blade. These vibrations create an impact on the cutting blade, which slices through the material with very little pressure. Moreover, the ultrasonic cutting method works on both soft and hard materials.

One of the best things about using an ultrasonic cutting machine is that it produces slices with a high aesthetic value. Unlike traditional cutting methods, ultrasonic cutting ensures a flat and clean cut. Conventional cutting processes use pressure on the food, which can lead to smearing and tearing. An ultrasonic cutting machine eliminates the problem by using vibrating blades, resulting in thin, flat slices.

The benefits of ultrasonic cutting machines are endless

PREV:Ultrasonic cutting machine is a device that uses ultrasonic frequency to cut various materialsNEXT:The features and applications of elastic tape cutting machine

Recommended Products

-

Computerized tape cutting machine (hot knife) distribution tape device JM-120H / 300M

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

-

Multifunctional Computerized Tape Cutting Machine (Hot Knife) JM-150H

Fully automatic cutting, simple operation, wide application range, high cutting quality, smooth c...

-

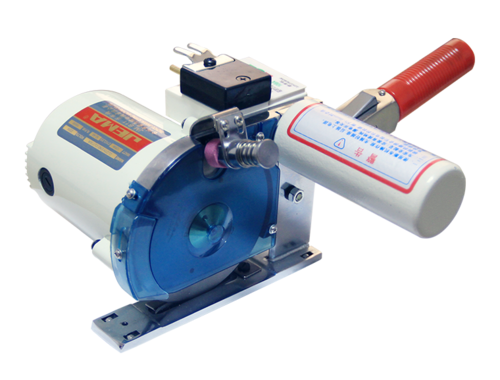

Fabric saving machine (fixed/flexible long handle) JM-B11

special function: Need to cut fabrics in large quantities, such as cotton, wool, and wire mesh...

-

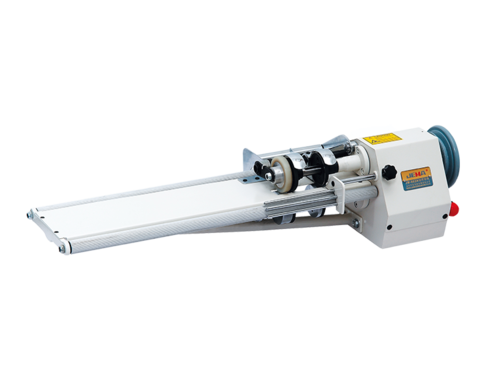

Cloth cutting machine JM-802A

special function: This sturdy machine is completely used for the manufacture of braided belts....

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语