Sale OEM Automatic Button Maker Feeding Fabric Machine Factory

In the intricate world of garment production, the finishing touches are what often set a product apart from its competitors. One such finishing detail that is frequently overlooked but is of paramount importance is the application of buttons. The Button Feeding Machine, a technological marvel in the field of garment finishing, has revolutionized the way buttons are installed, significantly impacting the quality of the product. This article explores the profound influence of the Sale Button Feeding Machine on the quality of garment finishing.

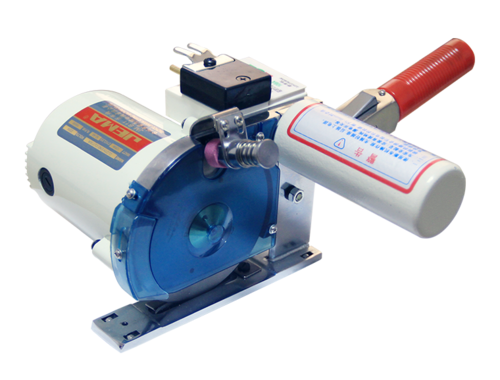

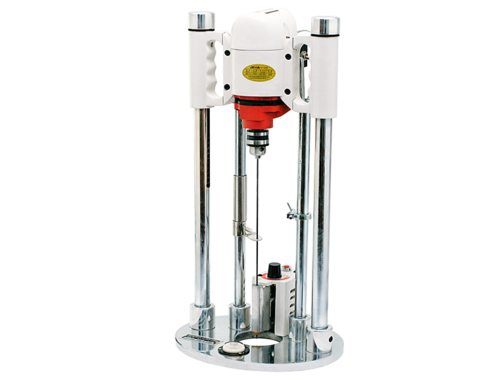

The Button Feeding Machine is an innovative device that automates the process of feeding buttons to sewing machines, ensuring a consistent and precise application. This machine has become an essential component in the garment industry, particularly for manufacturers who produce garments in large quantities. The impact of it on the quality of garment finishing is multifaceted, touching upon aspects such as speed, accuracy, and consistency.

One of the significant impacts of the Button Feeding Machine is the increase in production speed. Traditionally, button installation was a manual process, which was not only time-consuming but also prone to human error. The introduction of it has automated this process, allowing for a faster and more efficient workflow. This speed enhancement is crucial for manufacturers who need to meet tight deadlines and high-volume orders.

Accuracy is another area where the OEM Automatic Button Maker Machine excels. Manual button installation can result in misaligned buttons, uneven spacing, and other aesthetic issues that can detract from the overall quality of the garment. With its precision engineering, ensures that each button is placed exactly where it should be, every time. This level of accuracy is particularly important for high-end fashion brands that demand perfection in their products.

Consistency is a third key factor that the Button Feeding Machine contributes to the quality of garment finishing. In manual button installation, slight variations in the placement of buttons can occur from one garment to another, resulting in an inconsistent look across a product line. It eliminates these inconsistencies by providing a uniform button placement across all garments, ensuring a professional and polished appearance.

The Button Feeding Machine also plays a role in reducing material waste. By automating the button feeding process, the machine reduces the chances of buttons being dropped or misplaced, which can result in wastage. This not only saves on material costs but also aligns with the growing trend of sustainability in the fashion industry.

Moreover, the Button Feeding Machine contributes to the overall ergonomics of the production line. Manual button installation can be labor-intensive and result in repetitive strain injuries for workers. By automating this task, it reduces the physical strain on workers, resulting in a healthier and more productive workforce.

In terms of quality control, the Button Feeding Machine offers a significant advantage. With its automated system, the machine can be programmed to stop if a button is not properly fed, allowing for immediate detection and correction of any issues. This real-time monitoring and control enhance the overall quality assurance process.

The Button Feeding Machine also facilitates the use of a wider variety of button types. Some buttons, such as those with intricate designs or unusual shapes, can be challenging to install manually. With its adjustable settings, can accommodate a broader range of button styles, allowing for greater design flexibility.

The adoption of the Button Fabric Machine Factory can be a strategic move for garment manufacturers looking to enhance their brand reputation. A well-finished garment with perfectly placed buttons can leave a lasting impression on consumers, reflecting positively on the brand's attention to detail and commitment to quality.

In conclusion, the Button Feeding Machine is a transformative tool in the garment industry, significantly impacting the quality of garment finishing. Its ability to increase production speed, ensure accuracy, and maintain consistency, while also reducing material waste and improving worker ergonomics, makes it an invaluable asset. As the fashion industry continues to evolve, the Button Feeding Machine stands as a testament to the importance of innovation in maintaining high standards of quality and craftsmanship.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语