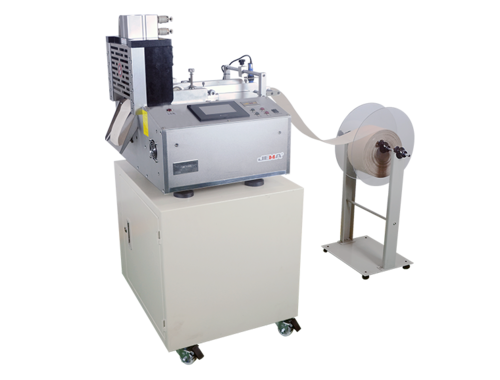

Computerized tape cutting machine (cold knife) JM-130L

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

In the realm of manufacturing and production, precision and efficiency are paramount. Auto Tape Cutting Machines have emerged as a cornerstone of these industries, offering unparalleled accuracy and speed in the cutting of various materials. This article delves into the diverse applications of Custom Auto Tape Cutting Machines, highlighting their adaptability and the significant impact they have on different sectors.

Auto Tape Cutting Machines are indispensable in the electronics industry, where precision cutting of tapes and films is crucial for the assembly of components. These machines ensure that each piece is cut to the exact specifications required, reducing waste and enhancing the quality of the product.

In the automotive sector, Auto Tape Cutting Machines are utilized for cutting gaskets, seals, and other components that require high precision. The machines' ability to cut materials quickly and accurately contributes to the streamlined production process, reducing manufacturing time and costs.

The textile industry benefits from the versatility of Auto Tape Cutting Machines, which can be adjusted to cut materials of varying thicknesses and textures. This allows for the creation of custom patterns and designs, catering to the unique demands of fashion and upholstery.

OEM Automatic Tape Dispenser Cutters play a critical role in the medical field, where consistency and cleanliness are non-negotiable. These machines are used to cut materials for medical devices, ensuring that each component meets the stringent quality standards required for patient safety.

For packaging purposes, Auto Tape Cutting Machines offer a high level of adaptability, capable of cutting a wide range of materials including paper, plastic, and foam. This versatility is essential for creating customized packaging solutions that meet the specific needs of various products.

The aerospace industry demands cutting-edge technology, and Auto Tape Cutting Machines meet these demands by providing precise cuts for materials used in aircraft components. Their ability to handle complex shapes and materials contributes to the innovation and advancement of aerospace technology.

Auto Tape Cutting Machines support sustainability by reducing material waste during the cutting process. This not only reduces costs but also aligns with environmentally conscious practices, making these machines a preferred choice for companies committed to eco-friendly operations.

The reliability of Auto Tape Cutting Machines is evident in mass production environments, where they consistently deliver high-quality cuts without the need for constant supervision. This reliability is crucial for maintaining production schedules and meeting consumer demand.

The versatility of Tape Slitting Machine in China is not limited to the types of materials they can cut but also extends to the range of applications they serve. From cutting intricate designs in textiles to creating precise components for electronics, these machines demonstrate their adaptability across industries.

Even for small-scale producers, Auto Tape Cutting Machines offer a cost-effective solution for cutting materials. Their ability to reduce waste and increase productivity makes them an attractive investment for businesses looking to optimize their operations without a significant capital outlay.

As technology continues to evolve, so do Auto Tape Cutting Machines. With ongoing advancements in cutting-edge technology, these machines are being equipped with features such as AI integration, IoT connectivity, and predictive maintenance capabilities, ensuring they remain at the forefront of manufacturing innovation.

Auto Tape Cutting Machines have proven their worth across a multitude of industries, offering a blend of precision, efficiency, and adaptability that is unmatched. As technology progresses, these machines continue to evolve, ensuring they remain a vital component in the ever-changing landscape of manufacturing and production. Their versatility is not just a selling point but a testament to their enduring value and relevance in a wide array of applications.

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

Fully automatic cutting, simple operation, wide application range, high cutting quality, smooth c...

Features It is mainly used for sewing flat buttons with two holes or four holes. If attac...

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...