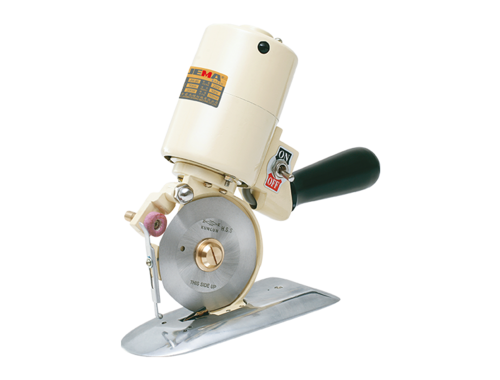

Computer tape cutting machine (cold knife) JM-120L

Fully automatic cutting, simple operation, wide application range, high cutting quality, c...

The advent of automation has revolutionized the way industries operate, and Auto Tape Cutting Machines stand as a testament to this technological leap. These machines have become an integral part of various sectors, streamlining processes and enhancing productivity. This article will explore the multifaceted role of China Auto Tape Cutting Machines across different industries, emphasizing their applications and the benefits they bring to the table.

In the electronics industry, the demand for precision is paramount. Auto Tape Cutting Machines are employed to cut adhesive tapes, insulating materials, and other components with high accuracy. This ensures that electronic devices are assembled with little error, resulting in improved product quality and reliability.

The automotive sector relies heavily on the efficiency of its production lines. Auto Tape Cutting Machines play a crucial role in cutting various tapes and materials used in car manufacturing, such as gaskets, seals, and insulation. The speed and accuracy of these machines contribute to faster production times and reduced waste.

The textile industry often requires customized cutting solutions for different fabrics and materials. They offer the flexibility to cut materials in various shapes and sizes, catering to the unique demands of fashion designers and manufacturers.

Medical devices require stringent quality control and consistency in their components. Auto Tape Cutting Machines provide consistent cuts for materials used in the production of medical tapes, bandages, and other related products, ensuring patient safety and device efficacy.

The aerospace industry demands high-precision cutting for lightweight materials used in aircraft construction. Auto Tape Cutting Machines are capable of handling these materials with the required precision, contributing to the innovation and advancement of aerospace technology.

In construction, materials such as tapes for sealing and insulation are essential. Auto Tape Cutting Machines ensure that these materials are cut to the exact specifications required, enhancing the reliability and durability of construction projects.

The packaging industry is increasingly focusing on sustainability. Custom Adhesive Tape Slitting Machines help reduce material waste by providing precise cuts, which is crucial for creating efficient and eco-friendly packaging solutions.

Beyond industrial applications, they also find use in the creative sector. Artists and crafters use these machines to cut intricate designs and patterns from various tapes and materials, adding a professional touch to their creations.

Food packaging requires clean, precise cuts to maintain hygiene and ensure the product's integrity. Auto Tape Cutting Machines are designed to meet these standards, providing consistent and clean cuts for food packaging materials.

The pharmaceutical industry requires rapid production of packaging materials to meet demand. Auto Tape Cutting Machines offer the speed necessary for high-volume production without compromising on quality.

R&D departments in various industries often need to prototype new materials and products. Gum Tape Cutting Machine Manufacturers provide the adaptability needed to cut samples and prototypes with precision, facilitating innovation.

For small-scale producers, Auto Tape Cutting Machines offer a cost-effective solution for cutting materials without the need for large, expensive machinery. This accessibility allows smaller businesses to compete in the market.

As industries move towards more integrated and automated systems, They are designed to fit seamlessly into these setups. Their ability to interface with other machinery and software enhances the overall efficiency of the production process.

Auto Tape Cutting Machines have proven their versatility across a spectrum of industries, from electronics to textiles, and from medical to aerospace. Their precision, efficiency, and adaptability make them an invaluable asset in the modern manufacturing landscape. As technology continues to evolve, the role of them is set to expand, further cementing their place in the future of industrial production.

Fully automatic cutting, simple operation, wide application range, high cutting quality, c...

Features The JM-60/70 miniature cutting machine is suitable for cutting curves, small arc...

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...

Features High speed: 120 pieces can be cut per minute. (Take 50mm length as an example) Hig...