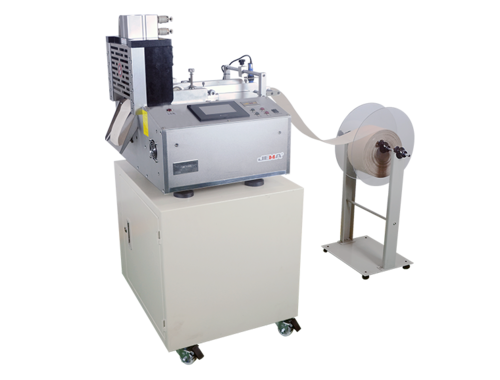

Computerized tape cutting machine (cold knife) JM-130L

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

Industrial Button Sewing Machines are essential tools in the garment manufacturing industry, known for their efficiency and precision in attaching buttons to various types of clothing. However, like any machinery, they can encounter issues that require troubleshooting to maintain production efficiency. This article aims to guide users through the common problems associated with China Industrial Button Sewing Machines and provide solutions to keep these machines running smoothly.

Before diving into troubleshooting, it's crucial to understand the basic components and functions of an Industrial Button Sewing Machine. These machines are designed to sew buttons onto garments with high precision and speed, making them indispensable in large-scale production environments. They typically consist of a needle bar, a presser foot, a bobbin winder, and a button attachment mechanism.

Common Issues and Solutions. One of the common issues with Industrial Button Sewing Machines is the skipping of stitches, which can result in buttons coming loose or not attaching properly. This can be caused by a variety of factors, including thread tension, needle condition, or bobbin winding. To resolve this, check the thread tension settings and adjust if necessary. Ensure the needle is not dull or damaged and replace it if needed. Also, make sure the bobbin is wound correctly and not too tight or loose.

Jamming can occur when the thread or fabric gets caught in the Industrial Button Sewing Machine, causing it to stop working. This can be due to improper threading, tangled threads, or fabric thickness. To troubleshoot, carefully rethread the machine following the manufacturer's instructions. Clear any tangled threads and ensure the fabric is not too thick for the machine's capabilities.

Broken needles are a common issue with Industrial Button Sewing Machines, often caused by sewing through thick layers of fabric or using a dull needle. To prevent this, use the appropriate needle size for the fabric thickness and replace needles regularly to maintain sharpness.

Inconsistent stitch length can affect the quality of the button attachment. This can be due to a malfunctioning stitch length regulator or a problem with the machine's timing. Check the stitch length regulator for any damage or misalignment and adjust it according to the manufacturer's specifications. If the issue persists, consider consulting a technician for a more in-depth examination of the machine's timing mechanism.

Thread breakage can occur due to excessive tension or poor-quality thread. To address this, adjust the thread tension to the recommended settings for the type of thread and fabric being used. Additionally, ensure that the thread is of good quality and not frayed or damaged.

Misaligned buttons can be a result of the Sewing Button Maker's presser foot not being level or the button attachment mechanism being out of position. Check the presser foot for any signs of wear or damage and replace it if necessary. Also, ensure that the button attachment mechanism is correctly aligned and adjusted according to the machine's manual.

Overheating can result in a decrease in the Industrial Button Sewing Machine's performance and even damage the internal components. If the machine is overheating, stop using it immediately and allow it to cool down. Regularly clean and lubricate the machine as per the manufacturer's instructions to prevent overheating and ensure ideal performance.

Unusual noises from the Industrial Button Sewing Machine can indicate a problem with the machine's internal components. Regular maintenance, including oiling and cleaning, can help reduce noise and prolong the machine's life. If the noise persists, it may be necessary to consult a professional for a thorough inspection and repair.

If the Industrial Button Sewing Machine is feeding fabric too slowly, it could be due to a clogged feed dog or a problem with the feed dog's spring. Inspect the feed dog for any debris and clean it if necessary. If the spring is weak or damaged, it may need to be replaced.

Wholesale Push Button Sewing Machines are complex pieces of equipment that, when properly maintained and operated, can significantly enhance the efficiency and quality of button sewing in the garment industry. By understanding the common issues that can arise and knowing how to troubleshoot them, manufacturers can reduce downtime and ensure that their production lines run smoothly. Regular maintenance, prompt attention to any issues, and adherence to the manufacturer's guidelines are key to getting these valuable machines.

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

Features JM-6070 micro cutting machine is suitable for cutting curves, small arcs and sma...

Features The JM-60/70 miniature cutting machine is suitable for cutting curves, small arcs and...

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...