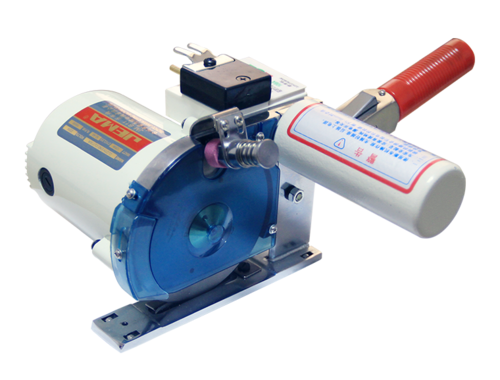

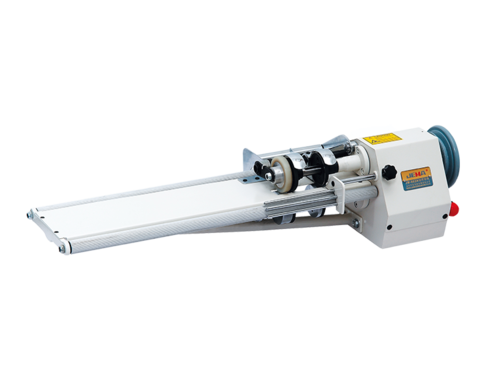

Sale Cheap Ultrasonic Knife Fabric Cutter Cutting Machine Price

The Ultrasonic Cutting Machine has emerged as a pivotal technology in various industrial sectors, revolutionizing the way materials are cut and processed. This advanced equipment offers a range of benefits that traditional cutting methods cannot match, making it an essential tool in modern manufacturing. This article delves into the applications of Sale Ultrasonic Cutting Machines, their advantages, and how they are transforming industries.

Ultrasonic Cutting Machines have gained popularity due to their ability to provide clean, precise cuts with reduced material distortion. The technology behind these machines utilizes high-frequency vibrations to cut through materials, offering an ideal alternative to mechanical cutting methods. This cutting-edge technology is now being employed across a spectrum of industries, from textiles to electronics, and from automotive to medical applications.

Applications of Ultrasonic Cutting Machines. In the textile industry, they are used to cut fabrics with high precision, avoiding fraying and ensuring a smooth edge finish. This is particularly beneficial for delicate materials like silk and synthetics, where traditional cutting methods can cause damage.

The electronics industry relies on Ultrasonic Cutting Machines for the precise cutting of components such as circuit boards and flexible printed circuits. The clean cuts provided by these machines help in maintaining the integrity of the electronic components.

In the automotive sector, Ultrasonic Cutting Machines are employed for cutting various materials, including leather, rubber, and plastics used in car interiors. The machines ensure clean cuts that are essential for the high-quality finish demanded by the industry.

Cheap Ultrasonic Knife Cutters play a crucial role in the medical field, where precision is paramount. They are used for cutting medical textiles, such as bandages and surgical gowns, as well as for cutting components of medical devices.

Advantages of Ultrasonic Cutting Machines. They provide highly accurate cuts, which is critical in industries where even a small error can result in significant consequences. The ultrasonic cutting process results in clean, burr-free edges, which is particularly important in applications where the cut surface will be visible or in contact with sensitive materials.

These machines reduce material waste by allowing for close-tolerance cutting, which is more efficient than traditional cutting methods. Ultrasonic Cutting Machines operate with significantly less noise compared to mechanical cutters, contributing to a safer and more comfortable working environment. The ultrasonic cutting process is more energy-efficient than traditional cutting methods, which is beneficial for both cost savings and environmental sustainability.

Despite the numerous advantages, Ultrasonic Cutting Machines also present some challenges. The initial investment cost can be high, and the machines require skilled operators to achieve ideal results. Additionally, the maintenance and replacement of ultrasonic cutting blades can be costly. However, the long-term benefits often outweigh these initial costs.

The integration of Ultrasonic Cutting Machines with automation systems has further enhanced their utility in industrial applications. Automated systems can increase the speed and efficiency of the cutting process, reducing labor costs and improving overall productivity.

As technology continues to advance, Ultrasonic Cutting Machines are expected to become even more sophisticated. Developments in software and hardware will likely result in improved cutting speeds, greater precision, and expanded material compatibility. The future of it looks promising, with potential applications in new industries and markets.

Ultrasonic Cutting Machines have proven to be a valuable asset in a variety of industrial applications. Their ability to provide clean, precise cuts with reduced material waste and noise makes them an attractive option for many businesses. As industries continue to evolve and the demand for high-quality products increases, the role of Ultrasonic Fabric Cutter Prices in modern manufacturing is likely to expand. With ongoing advancements in technology, these machines are set to play a crucial part in shaping the future of industrial cutting processes.

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语