The

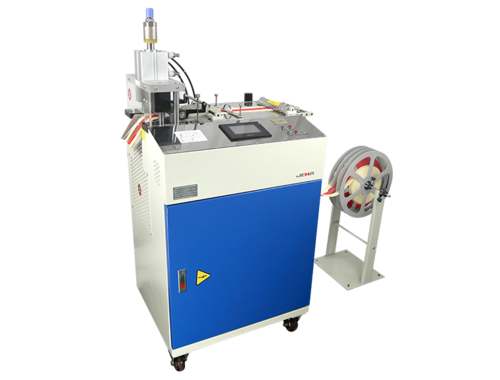

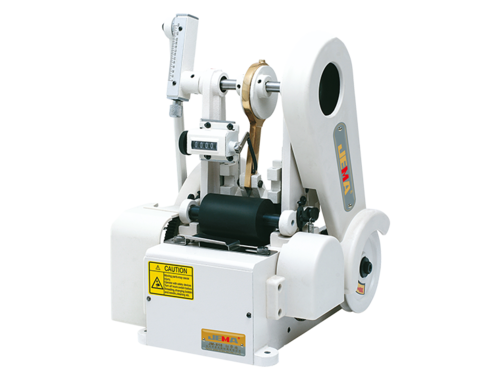

Ultrasonic Cutting Machine is a device that uses ultrasonic frequencies to cut a variety of materials. It consists of an ultrasonic transducer and oscillator. Both of these components work by using piezoelectric elements to create ultrasonic waves. This energy is then concentrated within the cutting area. This huge amount of energy melts and softens the material being cut. In addition to the high frequency, the machine also uses a relatively low cutting force to make the cut.

Ultrasonic cutting is an efficient way to cut materials without causing excessive wear and tear on them. This type of cutting machine is perfect for a variety of applications, including welding, sealing, and trimming materials without causing the edges to fray. It can even be used for cutting textile materials such as fleece and carpet.

The ultrasonic cutting process eliminates the risk of contamination or food shattering. This cutting technique has a number of advantages for food processing operations. It also offers a high degree of precision and can cut food items that were previously unsuitable for cutting with a traditional machine. Its auto-cleaning mechanism cleans the cutting blade automatically, so that the blade stays sharp for as long as needed.

Ultrasonic vibration also helps with small diameter holes. This vibration also reduces friction. The vibrational velocity of the drill helps in reducing the skidding and wandering of the drill at the hole entrance. It also minimises adhesion and helps to eliminate heat in the drilled hole. So, this cutting method can be used in a wide range of applications.