An

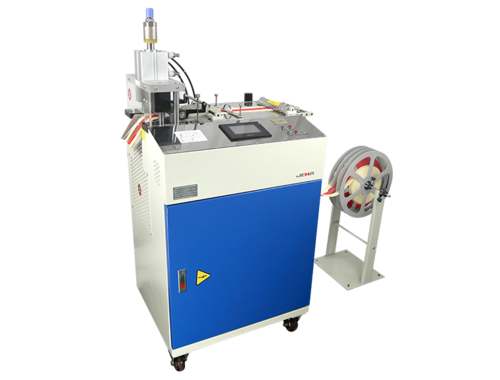

industrial button sewing machine is a specialized type of machine that is used to sew buttons onto garments and other textile products. It is typically used in the garment manufacturing industry and is designed to sew buttons quickly and efficiently.

An industrial button sewing machine is a type of sewing machine that is designed to handle heavy fabrics, and it uses a specialized needle and thread to attach buttons to a garment. The machine typically has a button clamp that holds the button in place while the needle and thread pass through the button holes, attaching the button to the garment.

The button sewing machine can be adjusted to accommodate different types and sizes of buttons and fabrics, and it can be used to sew on buttons made of different materials such as plastic, metal, and wood.

Some of the features that industrial button sewing machines might have are:

Adjustable button clamp: the button clamp can be adjusted to accommodate different types and sizes of buttons.

Adjustable sewing speed: the machine can be adjusted to sew at different speeds.

Adjustable presser foot: the presser foot can be adjusted to accommodate different types and thicknesses of fabrics.

Automatic thread cutting: the machine cuts the thread automatically after a button is sewn.

Safety features: such as a needle guard to protect the operator from injury.

The choice of an industrial button sewing machine will depend on the specific requirements of the application, such as the type of buttons and fabrics that will be used, as well as the production volume and budget.

.png?imageView2/2/w/500/h/500/format/jp2/q/100)