A

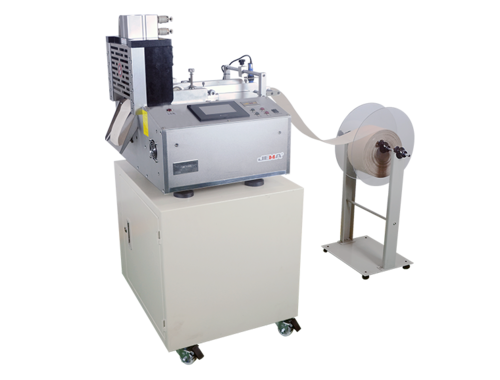

Multi-function Cutting Machine is a type of machine tool that combines multiple cutting methods or tools into one machine. These machines are designed to perform multiple operations, such as cutting, drilling, milling, and grinding, on a single workpiece. They are also known as multi-tasking, multi-process or multi-functional machines.

Multi-function cutting machines are used in a wide variety of manufacturing industries, including metalworking, woodworking, plastics, and ceramics. They can be used to create a wide range of shapes and forms, including flat surfaces, slots, grooves, holes, and more.

Some common types of multi-function cutting machines include:

5-axis machining centers: These machines use a spindle to move a cutting tool along five axes (X, Y, Z, A, and C) to remove material from a workpiece. They are commonly used to create complex shapes and forms.

Universal machining centers: These machines have the ability to perform a variety of operations, including turning, drilling, and milling on a single machine.

Swiss-type turning centers: These machines are similar to lathes but have a guide bushing that supports the workpiece and allows for more precise cuts. They are commonly used to create small and complex parts.

Combination machines: These machines combine multiple functions such as drilling, milling, sawing, and grinding into one machine.

Multi-function cutting machines are equipped with advanced features such as CNC control systems, high-speed spindles, and advanced cutting tools. They are widely used in manufacturing, aerospace, automotive, medical, and many other industries for their efficiency, accuracy, and flexibility.

In summary, Multi-function Cutting Machine is a type of machine tool that combines multiple cutting methods or tools into one machine to perform multiple operations on a single workpiece. They are also known as multi-tasking, multi-process or multi-functional machines. They are used in a wide variety of manufacturing industries, including metalworking, woodworking, plastics, and ceramics. They have advanced features such as CNC control systems, high-speed spindles, and advanced cutting tools, and are widely used for their efficiency, accuracy, and flexibility.