Details of a mechanical pick-and-place tape feeder

A mechanical pick-and-place tape feeder is a complex machine that reliably feeds carrier tape of varying pitches. It works by sending motion to all functions of the feeder from a single actuator lever. The details of a mechanical pick-and-place tape feeder are explained below.

To make the feeder, the design process starts with designing a design. The basic design criteria include low cost, low complexity, reliable operation, no esoteric electronics, no extra movements from the pick-and-place operation, and independence from overall machine calibrations. In addition, the design is modular, and it works with eight mm, 12 mm, and 16 mm tape. It is also compatible with paper tape and 1-hole component separation.

Functions of a linear guide in a mechanical tape feeder

The mechanical tape feeder contains several components. These components are placed on a carrier tape that has compartments, or tracks, for each component. The tape moves along a tape guide path, or track, that guides the component tape from the first tape engaging position to the second release position. The components are then picked up and placed onto a component mounting machine. This step is often referred to as the loading process.

In a mechanical tape feeder, the tape guide has a number of functions. The guide can be a separate force transmission unit or can be a single molded plastic part. In some systems, the guide is easily removed for repair or replacement. It is important to select a guide that fits your feeder model. Some mechanical tape feeders are compatible with many different types of tape.

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Web Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Product Search

Exit Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features ...

View this series of products

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features high speed: ...

View this series of products

Computer tape cutting machine (cold, hot infrared) JM-120HLR

Fully automatic cutting, simple operation, wide application range and high cutting quality. Features high speed: It can cut 70~90 pieces p...

View this series of products

Industry News

What are the functions of the tape feeder?

PREV:What are the application of a Mechanical Cutting Machine?NEXT:What factors need to be considered when buying the right ultrasonic cutting machine?

Recommended Products

-

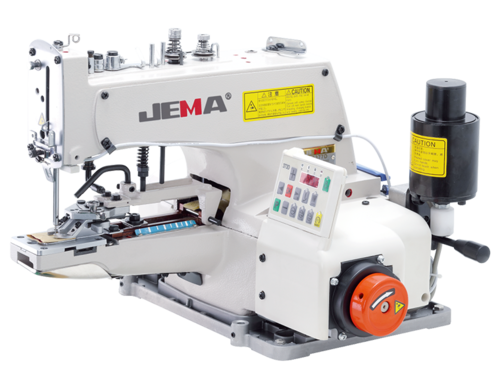

High-speed computer direct-drive button sewing machine JM-373D / 2377D

Features Quickly adapt to a variety of sewing requirements. Corresponding to the changes in sewing...

-

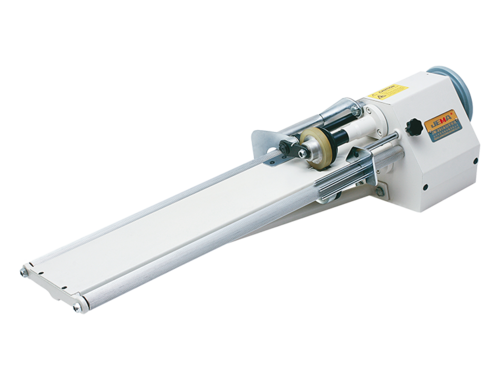

Cloth cutting machine JM-801A

special function: This sturdy machine is completely used for the manufacture of braided belts....

-

Micro cutting machine JM-60

Features JM-6070 micro cutting machine is suitable for cutting curves, small arcs and sma...

-

Electric cutting machine JM-103

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

©2021 Taizhou JEMA Sewing Machine Co., Ltd. Custom Elastic Tape Cutting Machine Manufacturers

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语