Before buying an ultrasonic cutting machine, you should consider the benefits of using this machine, what are some of the features you should look for, and the cost of purchasing one. In addition, you should consider the environmental benefits and how much the machine will cost you.

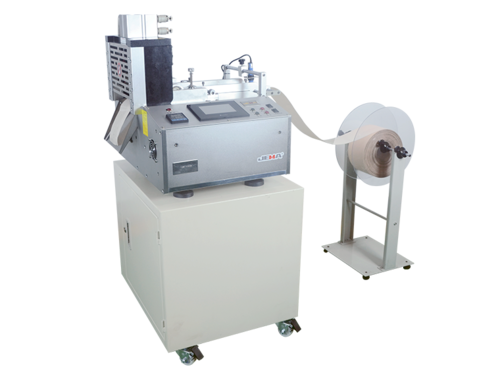

Samples of ultrasonic cutting machines

Ultrasonic cutting machines utilize vibration to cut materials. The ultrasonic vibration generated by a tool vibrates at a high frequency. This vibration reduces the cutting force required to cut a workpiece, while increasing the surface quality of the product. In addition, the vibrations can be tuned at specific resonance frequencies, providing maximum vibratory effects. Typically, ultrasonic cutting machines are used for small diameter workpieces, where the cutting speed is limited to the rotational speed of the workpiece.

Environmental benefits of ultrasonic cutting machines

Ultrasonic cutting is a clean method for laminating, embossing and slitting synthetic materials. Unlike thermal methods, which require an initial preheat cycle and considerable heat loss while running, ultrasonics eliminates both these processes. Additionally, ultrasonics eliminates the need for rotary unions and hoses. Moreover, ultrasonics can cut through a wide range of synthetic materials, including leather and plastic.

Compared to laser, ultrasonic cutting machines are highly efficient and provide better cutting quality. They can also be used for other industrial applications, including sealing materials. Furthermore, ultrasonic cutting machines can be integrated into industrial processes and help companies increase productivity and flexibility. Furthermore, they are recognized for their low environmental impact. In addition to their numerous advantages, ultrasonic cutting machines are easy to operate and are recognized as safe for industrial environments.

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Web Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Product Search

Exit Menu

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features ...

View this series of products

Computer tape cutting machine (cold, hot) JM-120LR

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and hot knives can be cut. Features high speed: ...

View this series of products

Computer tape cutting machine (cold, hot infrared) JM-120HLR

Fully automatic cutting, simple operation, wide application range and high cutting quality. Features high speed: It can cut 70~90 pieces p...

View this series of products

Industry News

Home / News / Industry News / What factors need to be considered when buying the right ultrasonic cutting machine?

What factors need to be considered when buying the right ultrasonic cutting machine?

PREV:What are the functions of the tape feeder?NEXT:What are the advantages of an automatic cutting machine?

Recommended Products

-

Computer tape cutting machine (hot knife) JM-130H

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and...

-

Button sewing machine JM-371

Features It is mainly used for sewing flat buttons with two holes or four holes. If attac...

-

Automatic button feeder JM-988

Features: 1. One-key width and thickness measurement function: When changing differe...

-

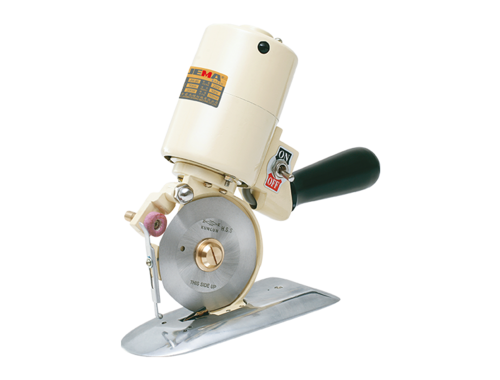

Round knife cutting machine JM-90

Features The JM-60/70 miniature cutting machine is suitable for cutting curves, small arc...

- Home

- About Us

- Product

- Ultrasonic Cutting Machine

- Multi-function Cutting Machine 150 Series

- Heavy Duty Cutting Machine 130series

- Auto tape cutting machine 120series

- Economic type cutting machine 110 series

- Mechnical Cutting Machine Series

- Automatic button feeder Series

- Industrial Button Sewing Machine Series

- Cutting Machine Series

- Tape Feeder

- Laser Cutter

- Customer Service

- News

- Contact Us

©2021 Taizhou JEMA Sewing Machine Co., Ltd. Custom Elastic Tape Cutting Machine Manufacturers

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语