An industrial button sewing machine is a type of sewing machine specifically designed for attaching buttons to fabric. It uses a specialized presser foot and needle to securely sew buttons onto the fabric. These machines are typically used in mass production settings such as garment manufacturing factories to increase efficiency and consistency in button attaching.

When operating an industrial button sewing machine, it is important to pay attention to the following:

Safety: Always make sure to follow safety guidelines and wear appropriate protective gear such as gloves and eye protection.

Threading: Ensure that the machine is properly threaded and the thread tension is set correctly.

Needle: Check that the needle is the correct size and type for the button and fabric being used.

Speed: Start at a slow speed and gradually increase to the desired speed.

Fabric: Make sure the fabric is properly secured and centered under the presser foot to prevent puckering or uneven stitching.

Button Placement: Ensure that the button is correctly placed and centered on the fabric before sewing.

Maintenance: Regularly clean and lubricate the machine to keep it functioning smoothly and extend its lifespan.

Troubleshooting: Familiarize yourself with common issues that may arise while operating the machine and how to fix them.

It's important to always follow the manufacturer's instructions and guidelines to ensure safe and efficient operation of the machine.

What should be paid attention to when operating industrial button sewing machines?

PREV:A computer tape cutting machine is a machine used to cut adhesive tape into specific lengthsNEXT:What are the common types of multi-function cutting machines?

Recommended Products

-

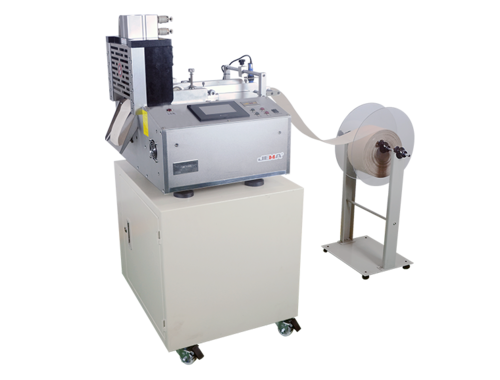

Computerized tape cutting machine (cold knife) JM-130L

Fully automatic cutting, simple operation, wide application range and high cutting quality. ...

-

.png?imageView2/2/w/500/h/500/format/jp2/q/100)

Multifunctional computerized tape cutting machine (cold knife) JM-150L

The automatic cutting machine is easy to operate, has a wide range of application, high cutting q...

-

Button sewing machine JM-373

Features It is mainly used for sewing flat buttons with two holes or four holes. If attached, it c...

-

Computerized tape cutting machine (cold, hot infrared) JM-110HLR

high functionality Speed: 95 pieces can be cut per minute. (Take 50mm length as an exampl...

英语

英语 中文简体

中文简体 西班牙语

西班牙语 越南语

越南语 葡萄牙语

葡萄牙语 土耳其语

土耳其语