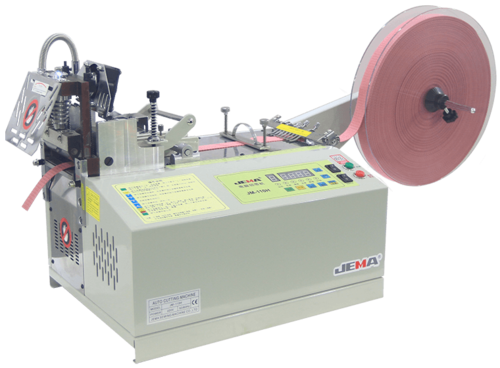

Computer tape cutting machine (hot knife) JM-110H

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and...

In the fast-paced world of the garment industry, where time is money and efficiency is key, the button feeding machine has emerged as a critical tool for streamlining production. This innovative piece of equipment has revolutionized the way buttons are attached to garments, significantly increasing productivity and reducing labor costs. The China Button Feeding Machine, with its precision and speed, has become an indispensable part of the modern garment factory.

The button feeding machine has come a long way since its inception. The process of attaching buttons to garments was a manual and time-consuming task. Workers would have to individually place each button and secure it with a thread, which was not only labor-intensive but also prone to errors. The introduction of it changed all that. It automated the process, allowing for a much faster and more accurate method of button attachment.

The button feeding machine operates on a simple yet effective principle. It uses a series of mechanisms to feed buttons into the sewing machine, which then attaches them to the garment. The machine is designed to handle a variety of button sizes and types, making it a versatile tool for any garment factory. Its efficiency lies in its ability to feed buttons at a consistent pace, ensuring that the sewing machine never runs out of buttons to attach.

The impact of the Sale Fabric Button Maker Machine on productivity in the garment industry cannot be overstated. By automating the button attachment process, the machine has eliminated the need for manual labor, which was previously a significant bottleneck in production. This has led to a substantial increase in the number of garments that can be produced in a given time frame. Furthermore, Its accuracy has reduced the number of defective products, which in turn has improved the overall quality of the garments produced.

One of the significant benefits of the Snap Button Press Machine Supplier is the cost savings it offers. By reducing the need for manual labor, garment manufacturers can save on wages and other associated costs. Additionally, the machine's efficiency means that fewer resources are wasted, resulting in a more sustainable production process. Its ability to handle a high volume of buttons also means that there is less downtime due to button shortages, further increasing productivity.

The button feeding machine's precision is another key factor in its success. The machine ensures that each button is placed accurately and securely, reducing the likelihood of buttons coming loose or falling off during wear. This not only improves the durability of the garments but also enhances their overall appearance. Consumers appreciate the neat and professional finish that provides, which can be a significant selling point for garment manufacturers.

Another advantage of the button feeding machine is its adaptability. The machine can be easily customized to handle different types of buttons and garments, making it a versatile tool for a wide range of applications. This adaptability allows garment manufacturers to produce a diverse range of products without the need for multiple machines or additional labor.

Despite its many benefits, the button feeding machine does present some challenges. One of the main issues is the initial cost of the machine, which can be a barrier for smaller garment manufacturers. However, the long-term cost savings and increased productivity often outweigh the initial investment. Additionally, the button feeding machine requires regular maintenance and skilled operators to ensure its performance. Training programs and support services can help address these challenges and ensure that the machine is used effectively.

As technology continues to advance, the button feeding machine is expected to evolve further. Future developments may include even greater automation, improved precision, and enhanced adaptability. The button feeding machine's role in the garment industry is likely to become even more significant as manufacturers continue to seek ways to increase efficiency and reduce costs.

In conclusion, the button feeding machine has played a pivotal role in increasing productivity in the garment industry. Its ability to automate the button attachment process has led to significant cost savings, improved quality, and enhanced efficiency. As the garment industry continues to grow and evolve, the button feeding machine will remain a crucial tool in the quest for a more productive and sustainable future.

Fully automatic cutting, simple operation, wide application range, high cutting quality, cold and...

Features The JM-3D/3/103 electric cutting machine is compatible with KMCK8-EU Eastman Ele...

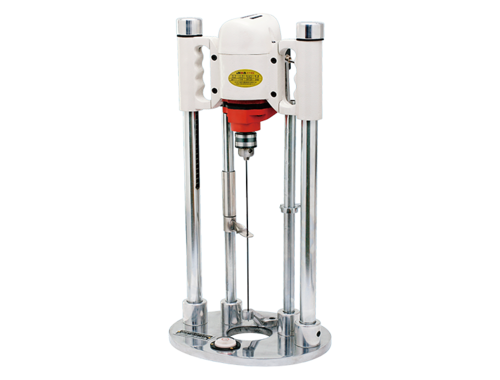

Features This machine is one of the indispensable special equipments in garment production. It...

Features The fully automatic computerized belt feeder is a new type of multifunctional belt fe...